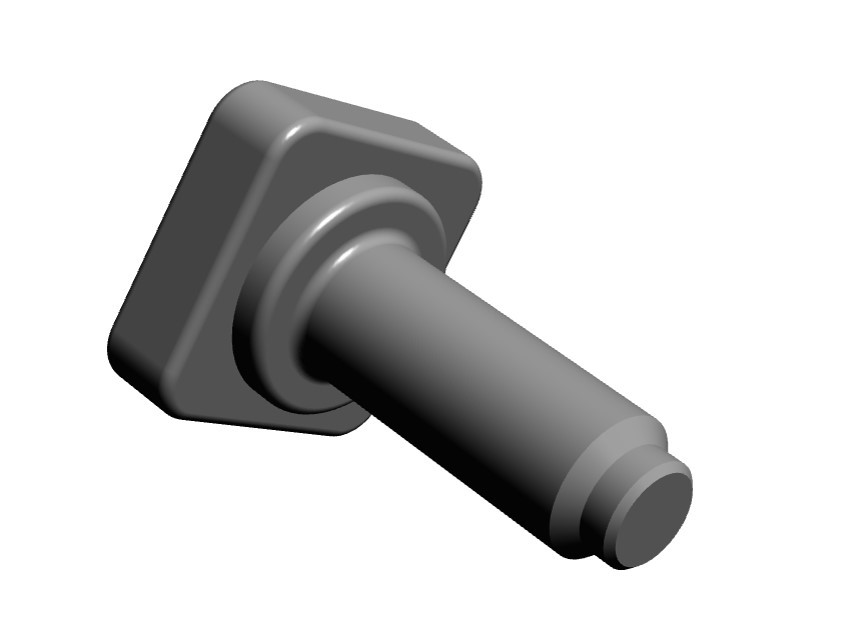

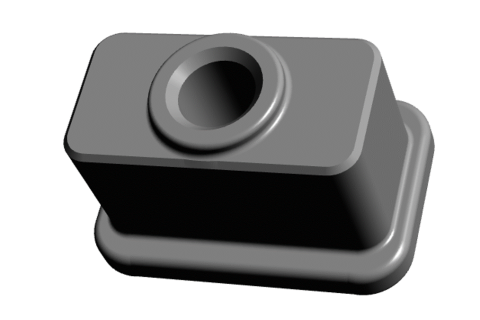

This example is a component of an automotive harness. It is characterized by its stepped and tapered design, but the most important feature is its square-shaped brim.

The bolt is insert-molded into the resin and must be secured so that it does not move in the resin, and the square shape of the head provides a non-turn function.

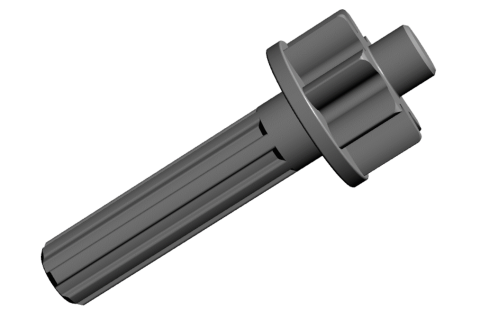

In this case, a 2D3B header was used instead of the conventional press forming process. The threaded part of the bolt is finished by rolling. As a result, the press process was reduced and the cost was lower than with the conventional method.

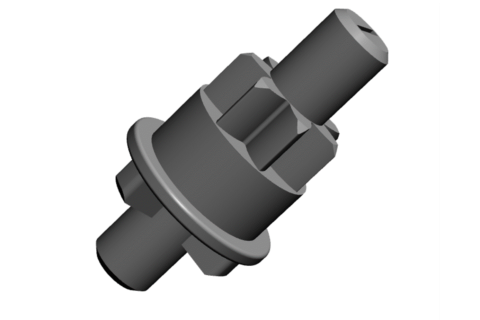

Arai Parts co., Ltd., which operates the "Cold Forging/VA/VE Center," is capable of proposing a change of production method from pressing and cutting, based on its ability to develop dies and propose molding processes.

Please contact us if you are considering cost reduction through a change of production method.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.