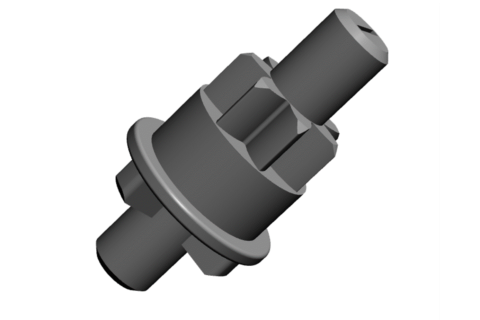

This example is a component of an automobile harness. Tin plating is used because it is used in a part that conducts electricity.

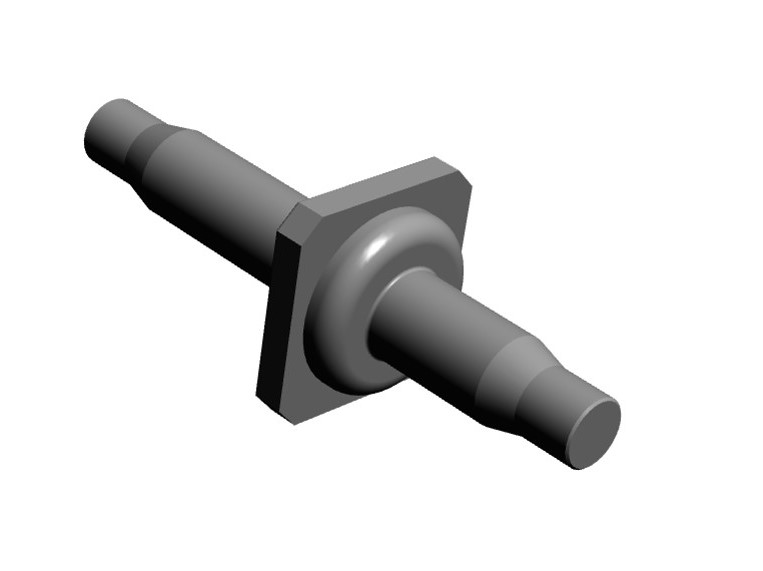

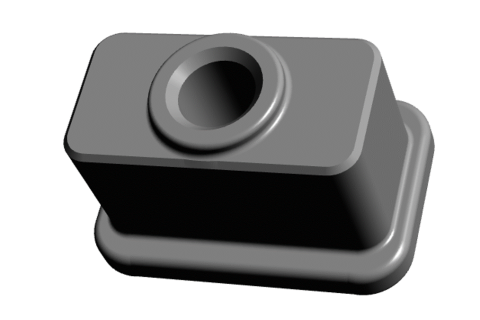

As shown in the photo, it is characterized by a square shape with a middle flange, a step, and a taper shape.

The reason for the rectangular shape of the inner tsuba is to provide a non-turn function after it is inserted into the resin.

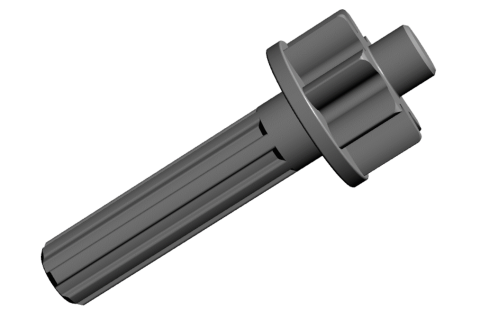

This product could have been machined entirely by cutting, but this would have been too costly, so the shaft and brim were roughly formed by heading, the inside flange was made square by press working, and the threaded part was finished by rolling.

The cost has been successfully reduced by forging the part with a header instead of cutting it entirely.

Arai parts Co., Ltd. operates the "Cold Forging/VA/VE Center" and proposes numerous cost reductions through conversion of production methods. We have a wealth of VA/VE proposals with more than 130 cases per year, so please contact us if you have any questions.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.