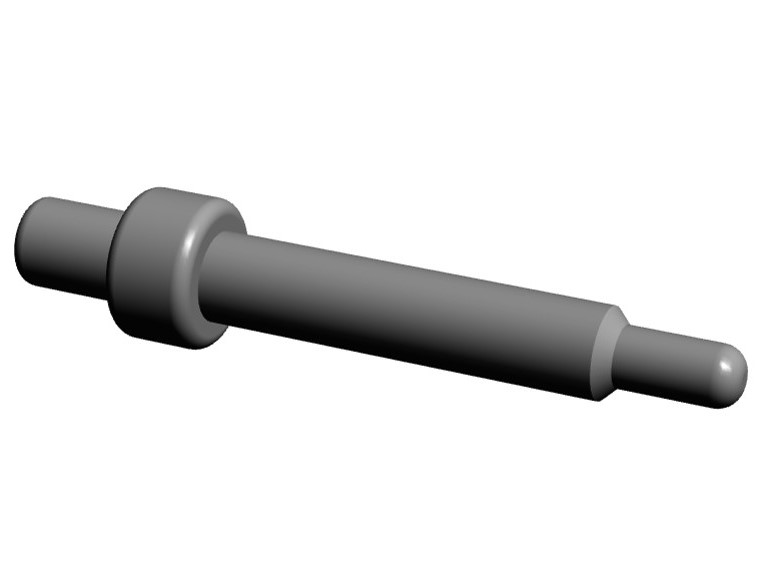

This example is a component of an automobile harness, made of SWCH10R.

One of the features of this case is that the finishing process for the tip of the harness was reviewed. In the past, finishing was performed by cutting. However, the customer consulted with us about changing the method with cost reduction in mind, and we proposed replacing cutting with rolling.

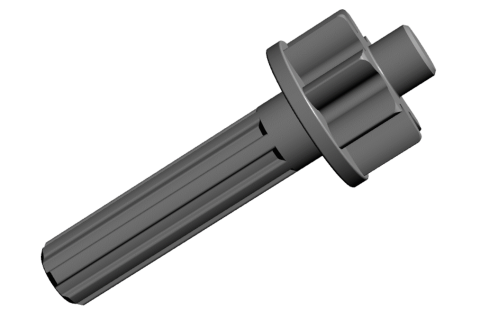

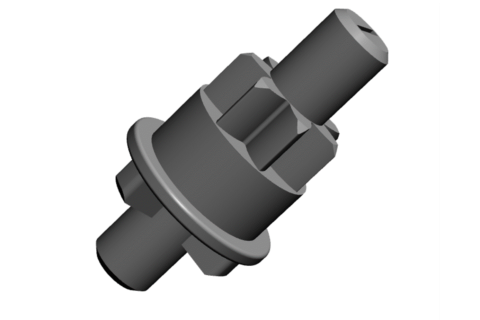

The entire shaft section is machined using a 2D3B header, and the tip is finished by rolling.

By reviewing this process, we succeeded in reducing the cost per piece.

At Alrai parts Co., Ltd. which operates the "Cold Forging/VA/VE Center," engineers with knowledge of numerous methods will propose the most suitable method for your products and provide results that satisfy you in terms of QCD.

Please contact us if you are considering cost reduction through conversion of production methods.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.