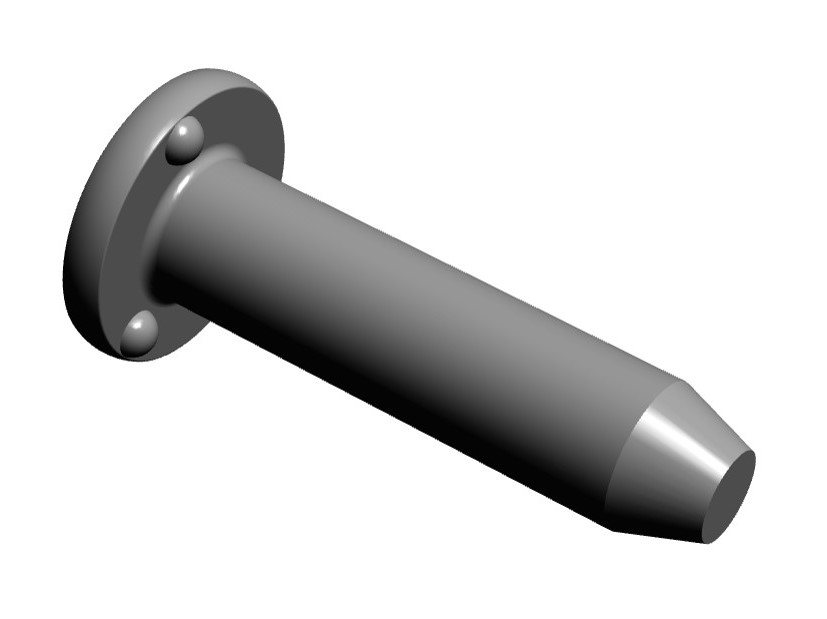

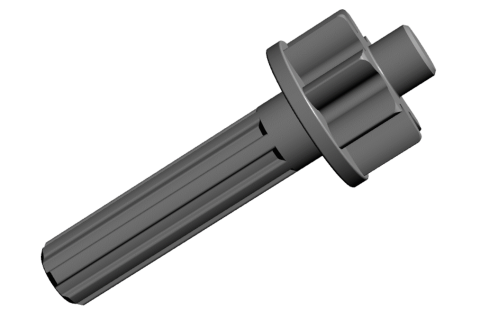

This example is a projection bolt for automobile seats. It is characterized by the projection and the tapered shape at the end of the shaft as a guide. (There is a thread designation on the shaft.)

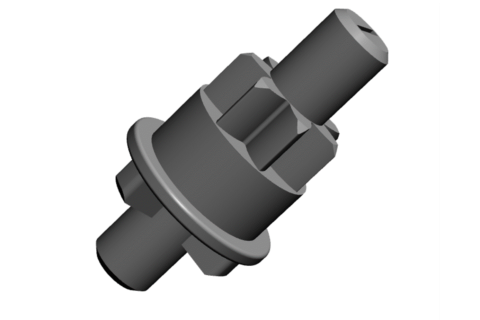

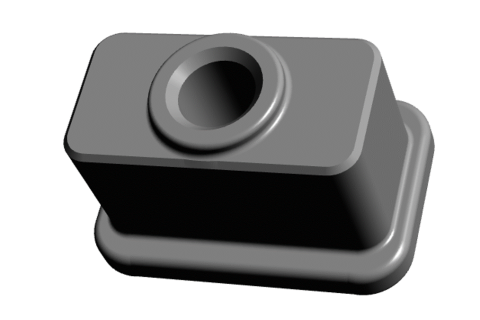

Therefore, this time, after forming by 2D3B header machine, finishing process by cutting and rolling was applied.

In this case, the forging was done after cutting, so that heat treatment was not required for the raw material due to the hardness of the material.

Arai Parts Co., Ltd. which operates "Cold Forging/VA/VE Center" has a lot of experience in manufacturing bolts and pins, and promises to provide products with excellent QCD by combining cutting and rolling in an appropriate manner. Please consult with us if you are in need of mass production.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.