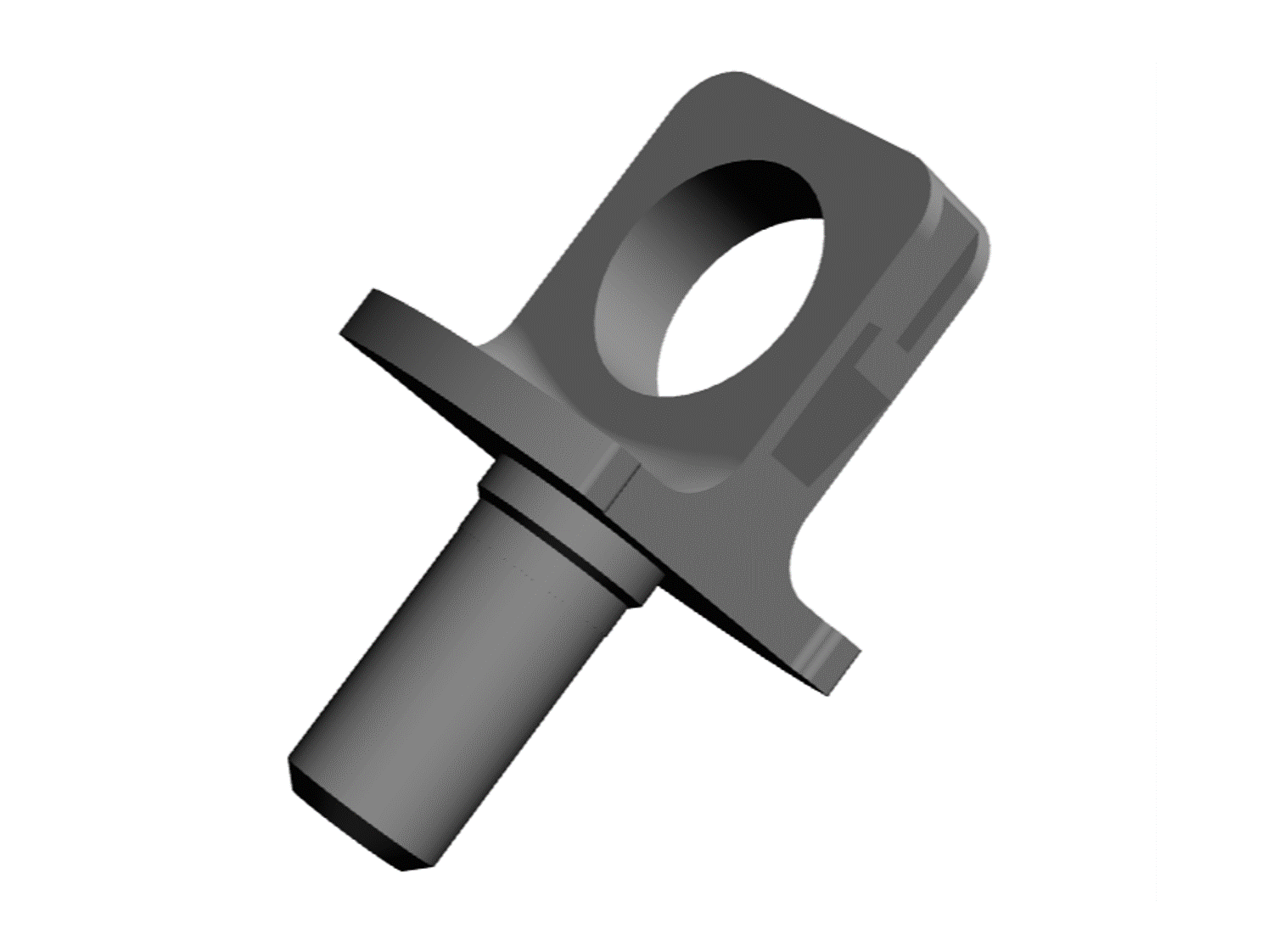

This example is a bolt for automobile seat rail.

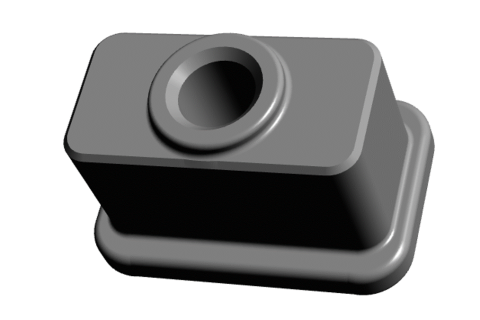

One of the features of this bolt is that it has a hole machined perpendicular to the shaft. This shape is difficult to forge alone, so we had to fully consider how much of the product should be forged and how much should be machined.

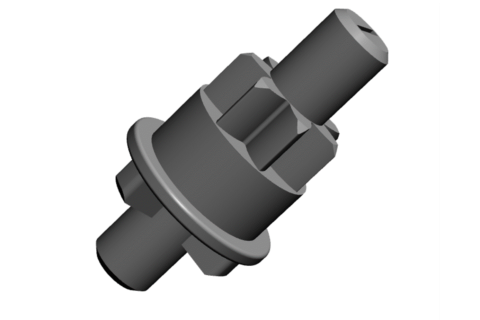

Originally, this was a separate product, but the customer requested a cost reduction, so we proposed forging (integration) of the two parts and moved to mass production.

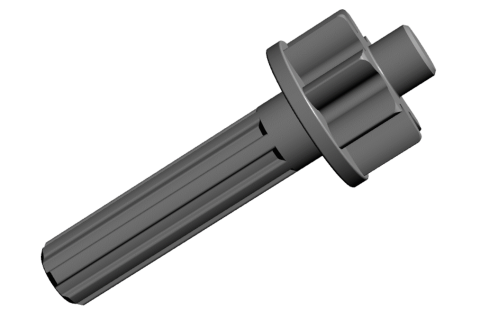

After forming the basic shape using a parts former, the shaft part was knurled by rolling, and the stepped flange seat surface was finished and drilled by cutting.

Arai Parts Co., Ltd. which operates the "Cold Forging/VA/VE Center" has abundant experience in manufacturing parts with complex shapes such as this product by combining multiple production methods centered on cold forging. If you are having trouble with mass production of bolts and pins, please contact Alai Parts.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.