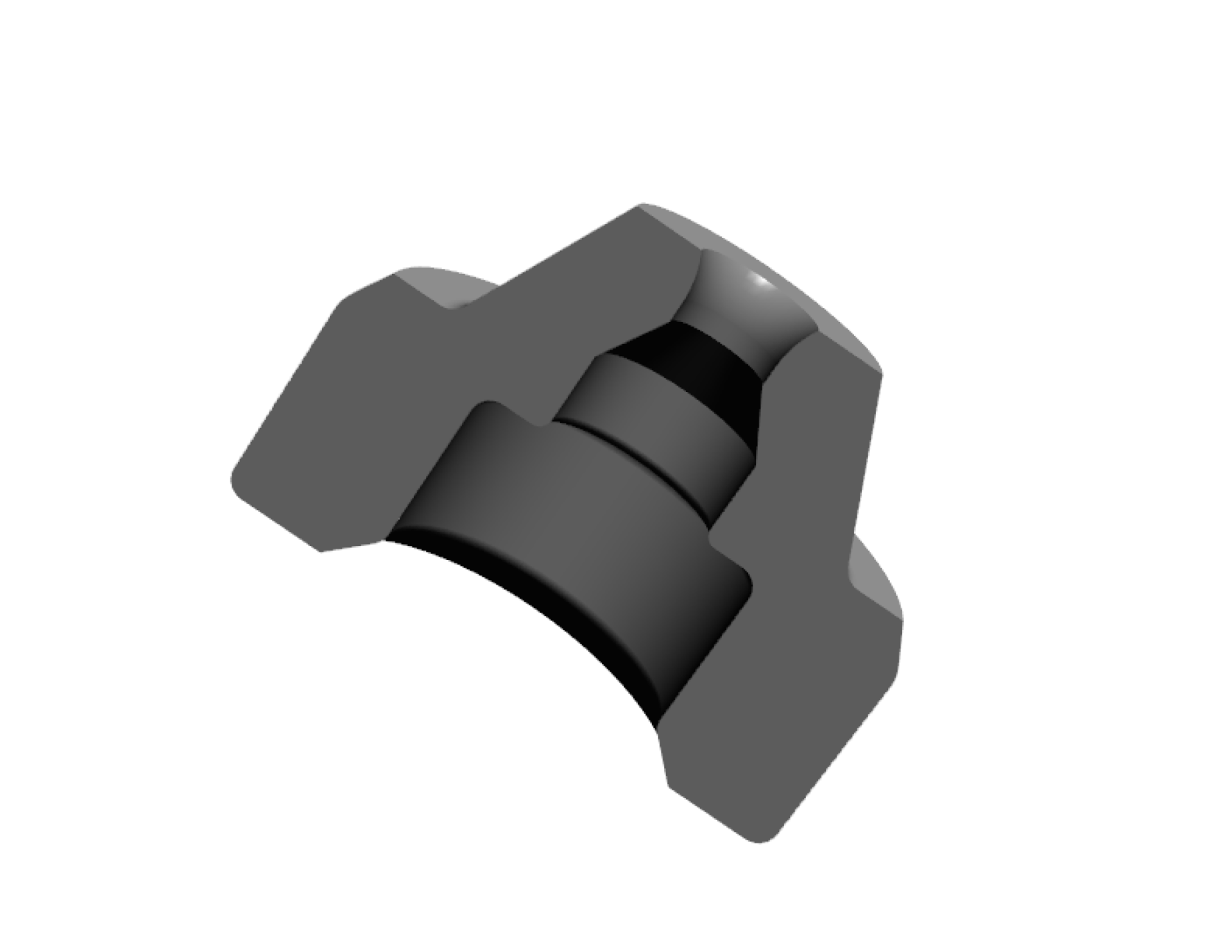

This case is an auto tensioner part for automobiles. It is technically a very difficult product because it features a narrow hole and tapered inner and outer diameters, with a tapered through-hole on the inner diameter in particular.

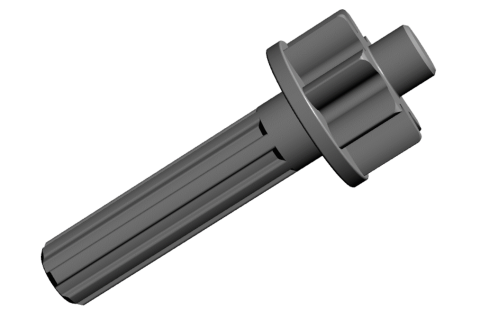

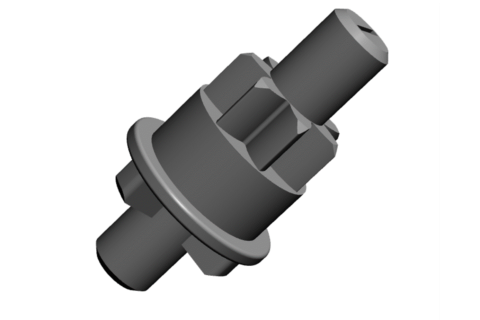

The product had been conventionally formed by sintering, but we considered converting to forging at the request of our customer for cost reduction.

However, by using our forging technology and expertise in converting to a forging process, we were able to produce the same product using only a parts former.

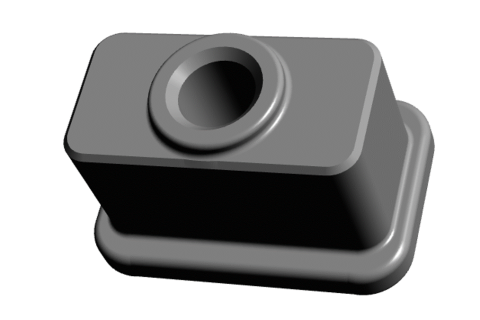

Arai Parts Co., Ltd, which operates the "Cold Forging/VA/VE Center," can also realize cost reductions by converting the production method from sintering. Please contact us if you have any questions about cost reduction of sintered or machined products.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.