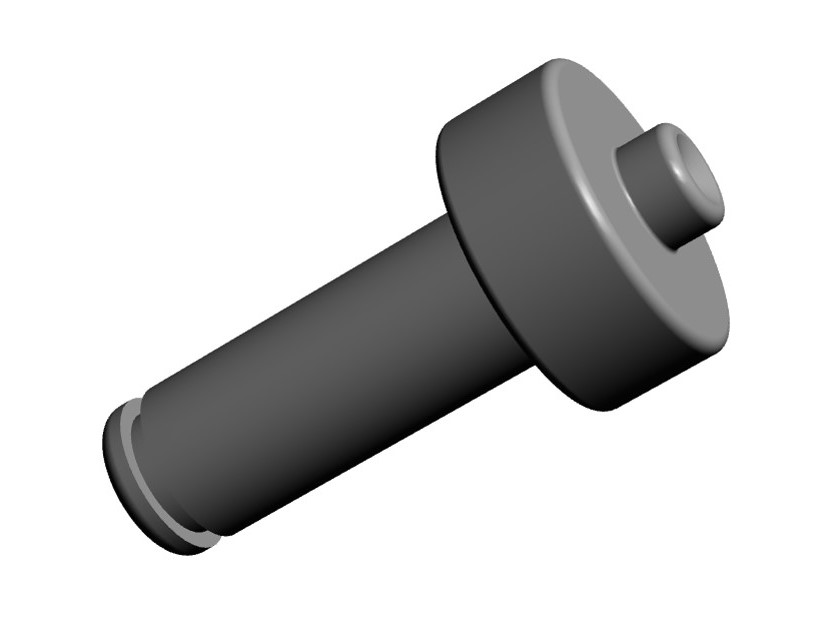

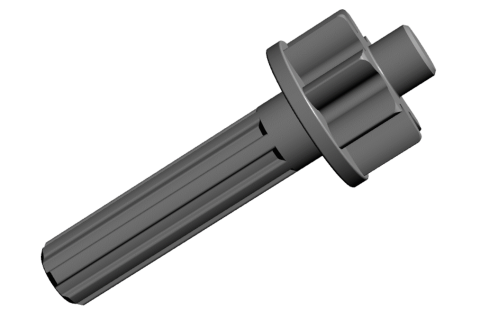

This example is a component of OA equipment. One of the features is the groove at the tip of the shaft.

Until now, all cutting was used and the shape was realized by machining from a round bar. However, cutting requires a large amount of machining allowance and machining time, resulting in higher costs.

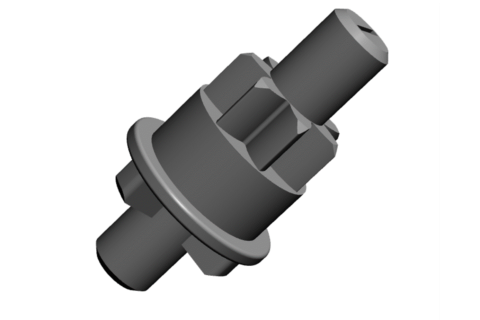

Therefore, we proposed a method in which the groove forming cutting is replaced by rolling and all forming of the shaft and brim is done by forging. Compared to the case where all cutting is used, we have succeeded in significantly reducing costs by reducing material loss and machining time.

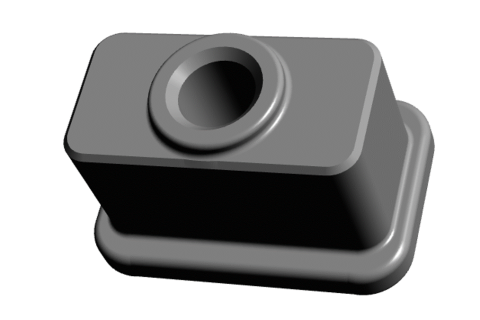

For shafts, bolts, and other shaft products, we sometimes see products that are "cut for now because they have been cut in the past. Arai Parts Co., Ltd. operates the "Cold Forging/VA/VE Center" and asks if it is possible to reduce costs by all or partial forging of these shaft products. We are looking forward to hearing from you. If you have a project in mind, please contact us.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.