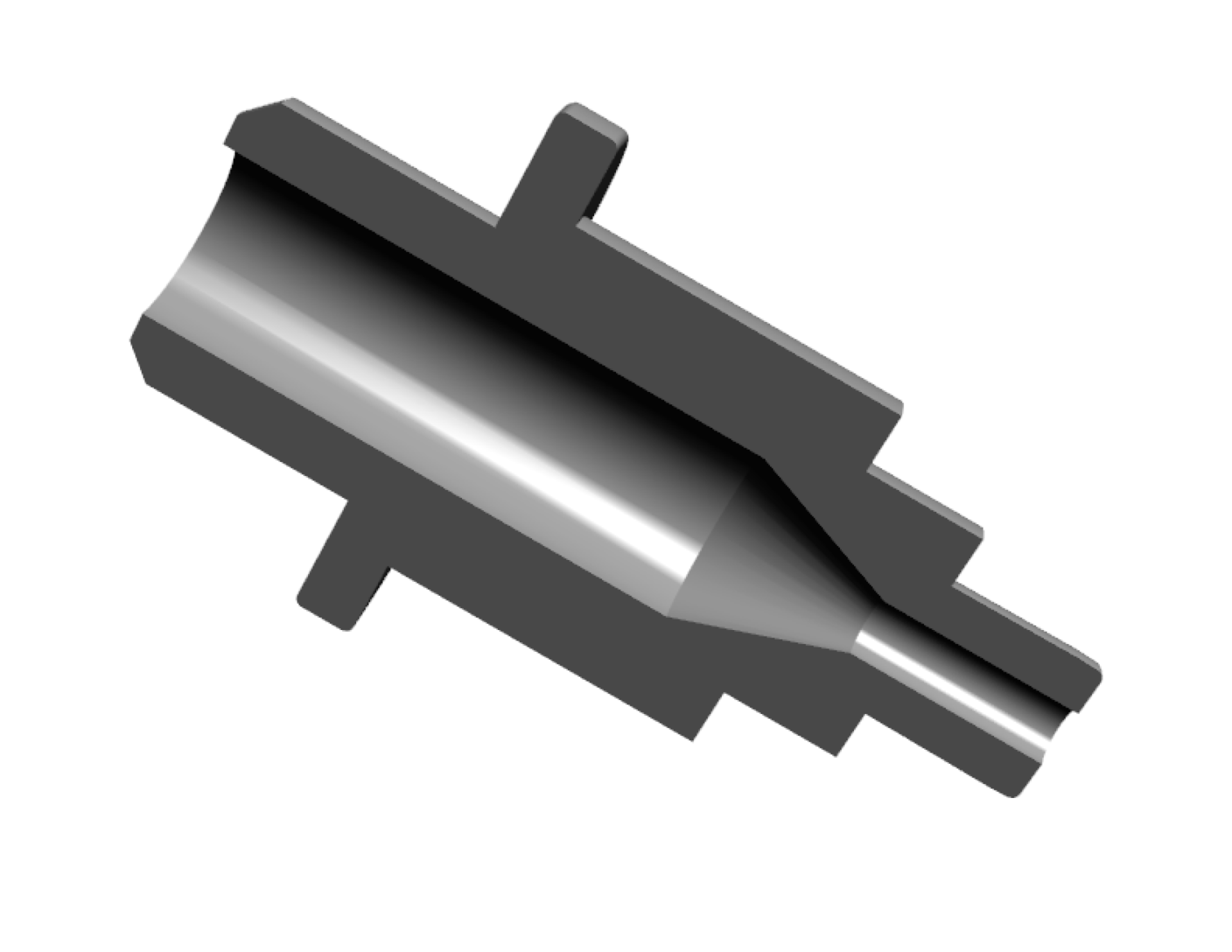

This example is a rivet used for automobile doors. The product features a Φ6 hole and a Φ2 narrow hole connected by a taper and penetrating.

In the past, this was handled by cutting, but the machining process was difficult and production capacity could not be increased.

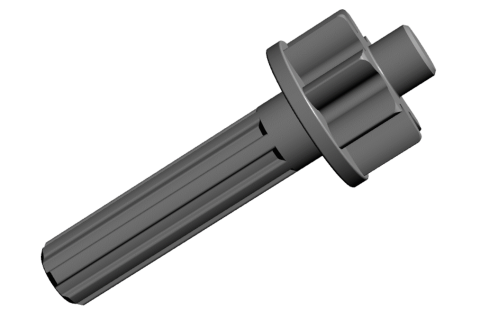

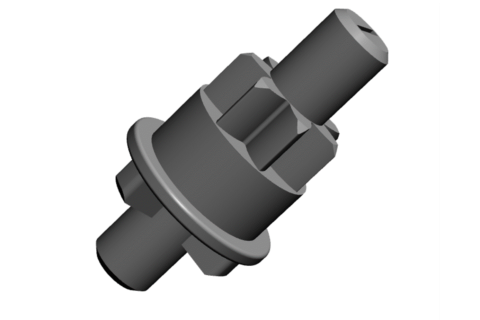

By utilizing our 7-, 8-, and 9-step parts formers and die development capabilities, we were able to forge complex shapes that were thought to be "only possible by cutting" and achieve significant cost reductions by increasing production capacity and reducing man-hours. In this case, too, we succeeded in reducing costs by forging and cutting, whereas other companies would have had to perform all cutting.

Alai Parts Co., Ltd. operates the "Cold Forging/VA/VE Center" and contributes to cost reductions by realizing material loss reductions and man-hour reductions through the partial forging of products that were previously subjected to full cutting. Please contact us if you have any questions.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.