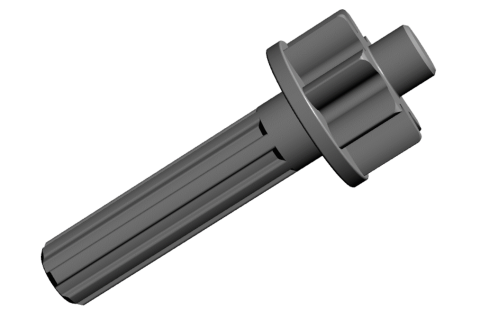

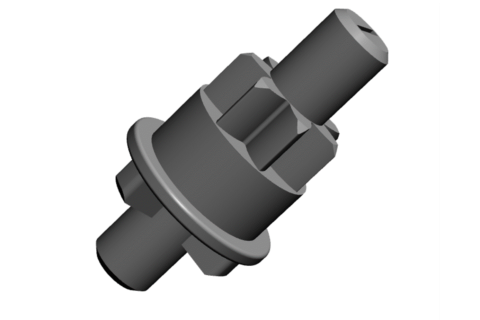

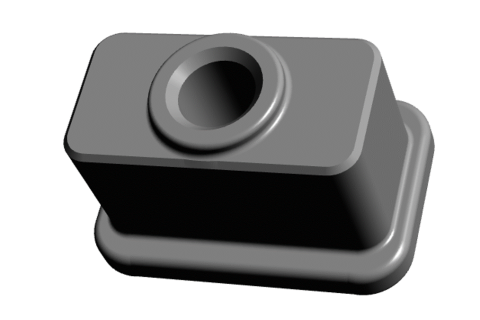

This example is a special nut for automotive engine parts. It is a product that has both conduction and fixing applications. As you can see in the image, the shape of the product is extremely complex, and the customer was considering using a multi-axis multitasking machine to cut it. However, the cost was a bottleneck because of the large machining allowance required for all cutting.

Therefore, we proposed manufacturing by a combination of multiple methods centered on cold forging. As a result, a significant cost reduction was achieved compared to the total cutting process.

Arai Parts Co., Ltd. which operates the "Cold Forging/VA/VE Center" is also capable of converting the manufacturing method for complex shapes that can only be achieved with a multi-axis multitasking machine, as in this product, and can realize significant cost reductions compared to all-cutting. Please contact us if you have any trouble with mass production of special nuts and collars.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.