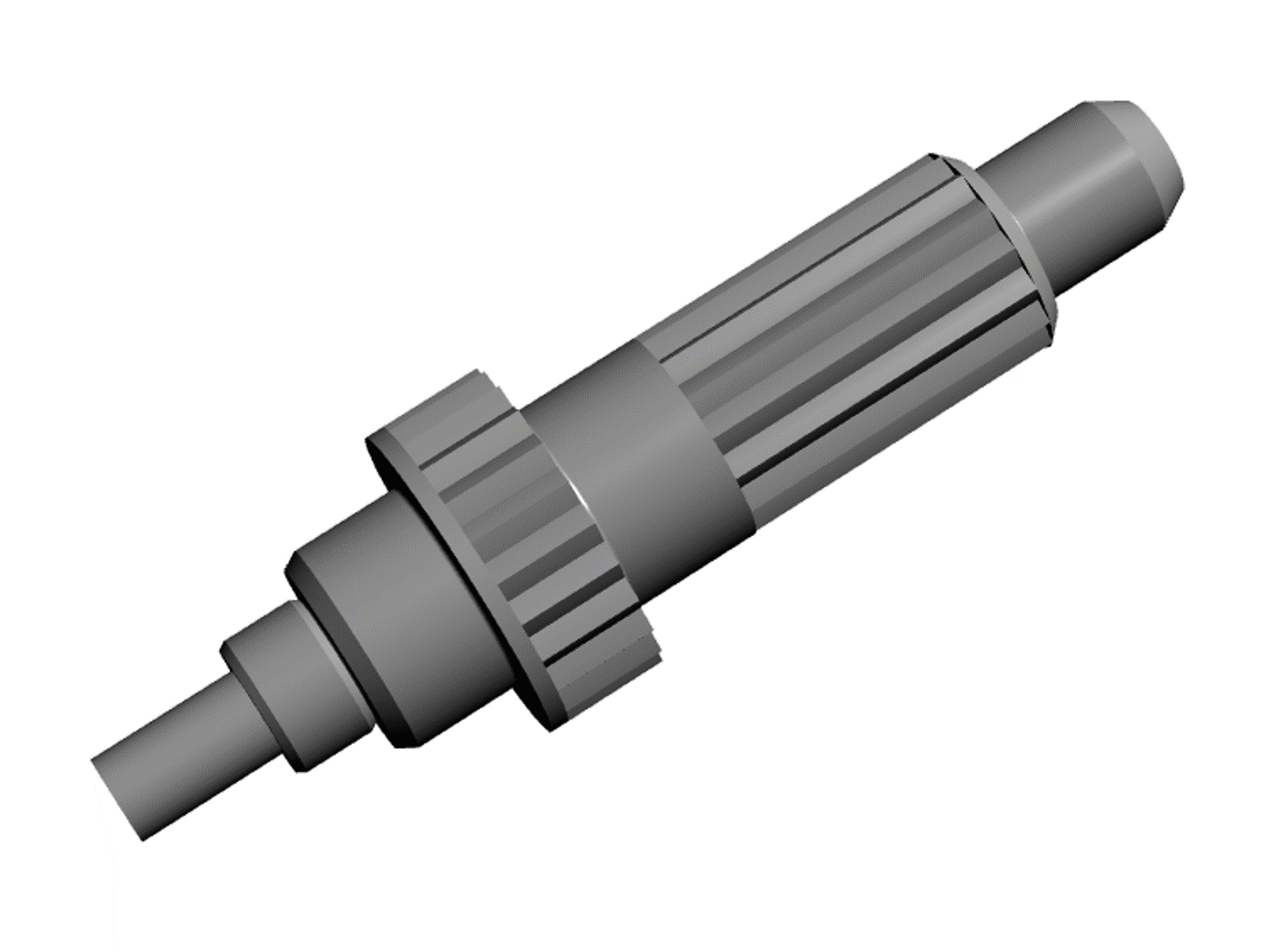

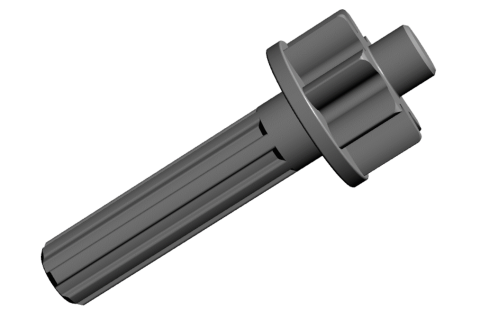

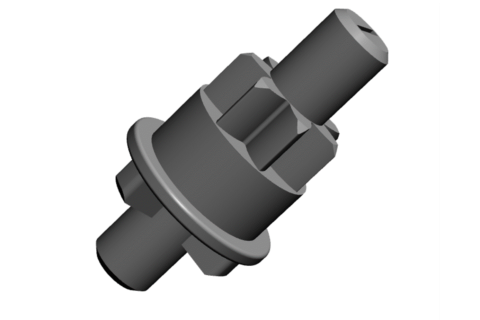

This example is a gear shaft used in power sliding doors of automobiles. The product features two different gear sections with different numbers of teeth and strict accuracy requirements.

Gear shafts are generally made by sintering + cutting or full cutting, but in this case, we succeeded in reducing costs by forging a part of the process.

Furthermore, where other companies perform "parts former + rolling + cutting + grinding," we have achieved a grinding-less process by making full use of our 9-step former and die development capabilities to perform "parts former + rolling + cutting. This process is highly cost-effective.

Arai Parts Co., Ltd. which operates the "Cold Forging/VA/VE Center" has abundant experience in manufacturing high-precision gear shafts such as this product.

If you are having trouble with mass production of gear shafts, please contact Alai Parts, a specialist in cold forging and rolling.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.