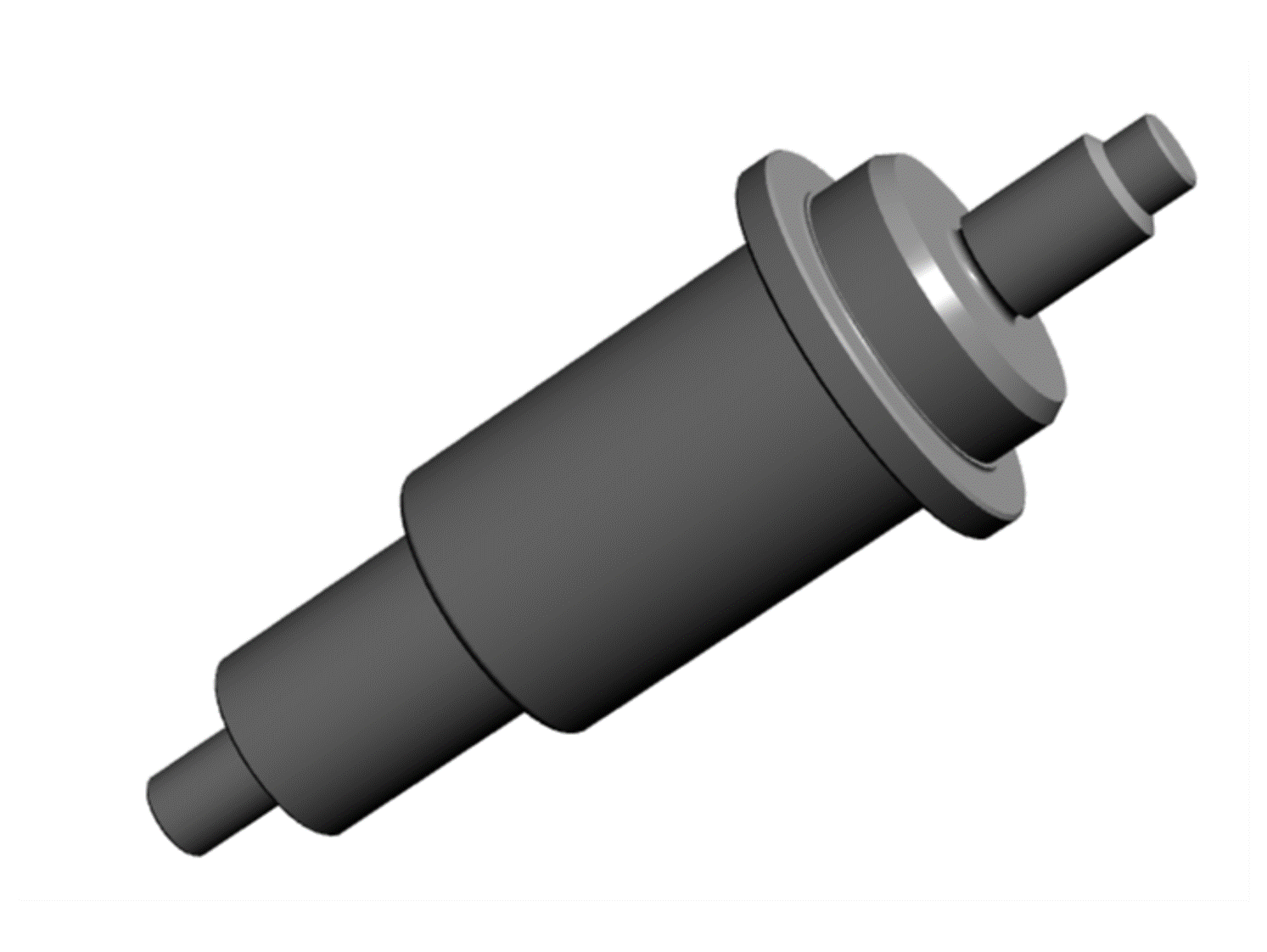

This case is a bolt (M5 and M6 threads on both ends) used in an automotive inverter.

The customer requested "accuracy close to that of a fully machined bolt, as well as minimizing scratches and dents on the shaft and threaded part. However, the shaft diameter at both ends of the product was too narrow and required secondary machining after heading. In addition, the product was heavy in weight and involved many processes, making it prone to dents.

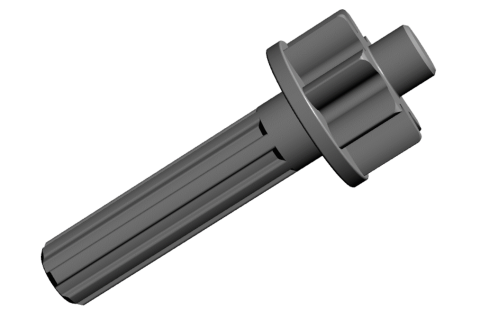

Therefore, we decided to develop a new type of product that is

(1) Consideration of the order of heat treatment and plating in the post-process

(2) Ensure that the plating thickness does not affect the required accuracy of the threaded part.

(3) Tried various types of plating such as barrel plating and suspension plating

We studied various process designs and construction methods.

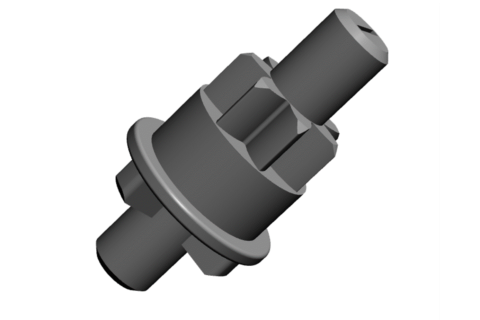

As a result, we were able to meet the customer's accuracy and quality requirements and move into mass production.

Arai Parts Co., Ltd. which operates the "Cold Forging/VA/VE Center" has abundant experience in manufacturing high-precision bolts comparable to machined products such as this product. If you are having trouble with mass production of bolts, please contact Alai Parts Co.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.