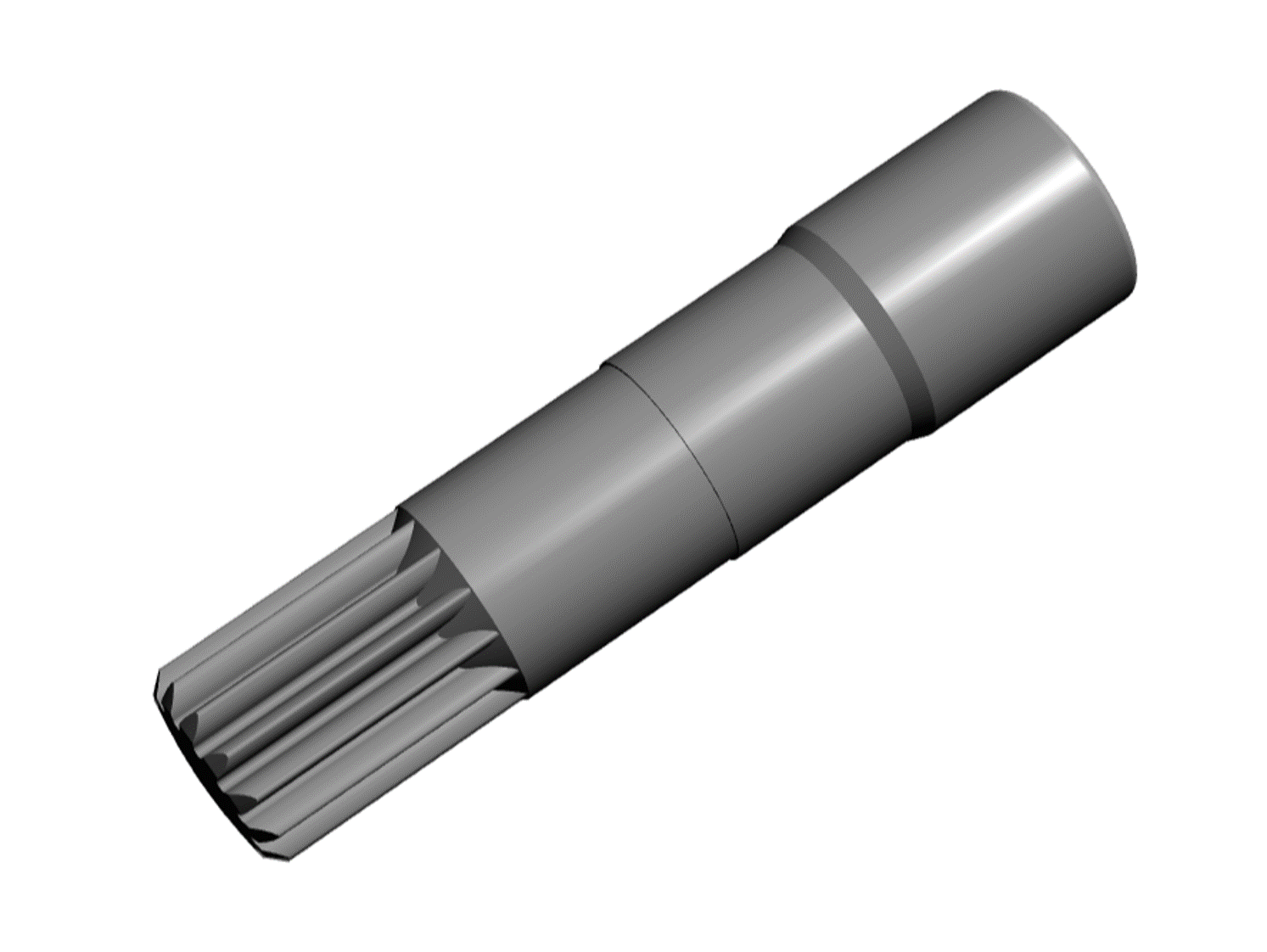

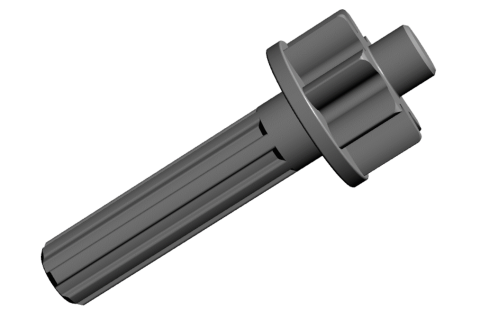

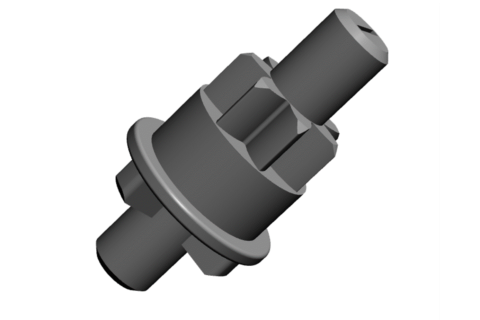

This example is a mechanical part for an automobile sliding door. It features an involute shape and is made of SCM415.

With the conventional method, the parts transfer during rolling was not stable, and sufficient accuracy was not achieved.

This time, by devising a way to transport the workpiece after forming in the header, the orientation of the workpiece at the time of feeding into the form rolling is stabilized, and highly accurate form rolling is realized.

Since the gears used in this case were high-precision gears, cutting and polishing were also performed after rolling.

Aliparts Co., Ltd. operates the "Cold Forging/VA/VE Center," and based on its many years of experience, can propose the optimum method for the mass production of high-precision gear parts.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.