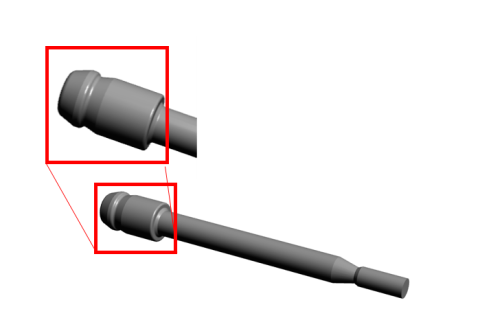

This is an example of a case in which a change in manufacturing method for shafts became an issue. The flow volume has increased significantly due to the development of new automobile models in which this product will be incorporated, resulting in a large increase in lot size. However, the customer consulted us on the need for a review of the existing production method, as it was both unproductive and expensive.

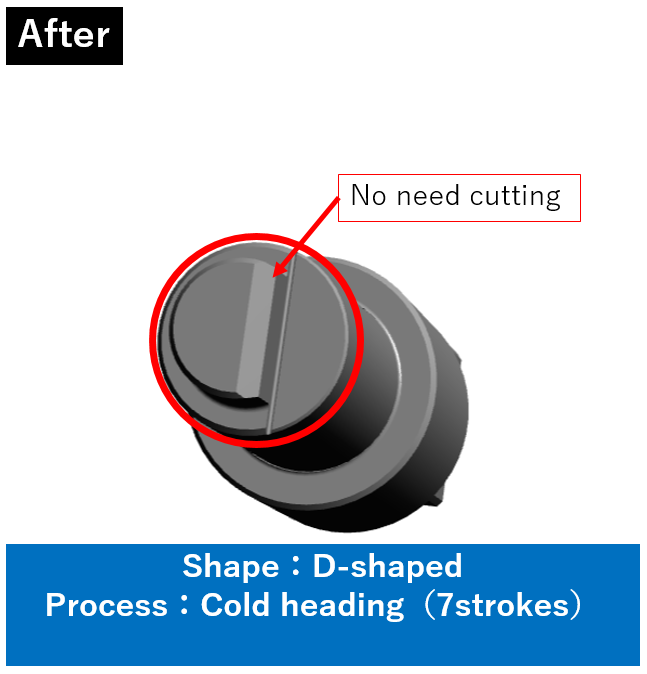

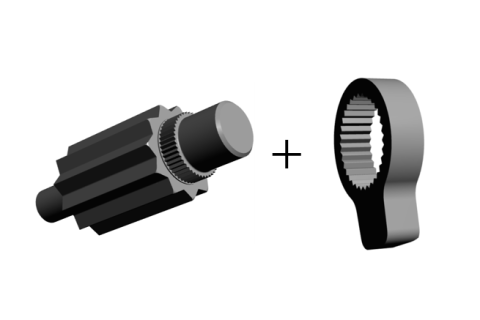

In response to a specific challenge, we forged the D-cut portion that had been cut.

The material was stainless steel, which is hard and technically challenging.

However, by changing the equipment used from a 5-stage to a 7-stage parts former and performing preliminary forming, forming became possible.

As a result, we were able to reduce (1) cost, (2) man-hours, and (3) lead time, and also stabilize the dimensions of the D part by molding it with a die.

We consulted with you about productivity improvement and cost reduction of shafts. In this case, cost reduction was achieved by cold forging the D-cut shape.

If you have any questions about converting production methods, please contact our Cold Forging/VA/VE Center.

We can solve your problems with our cold forging and cold heading die design and development capabilities, and with over 100 pieces of manufacturing equipment, including 9-stage parts formers.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.