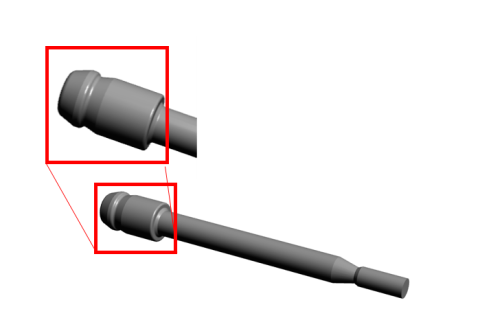

This is an example of cost reduction by reviewing the processing method of pins.

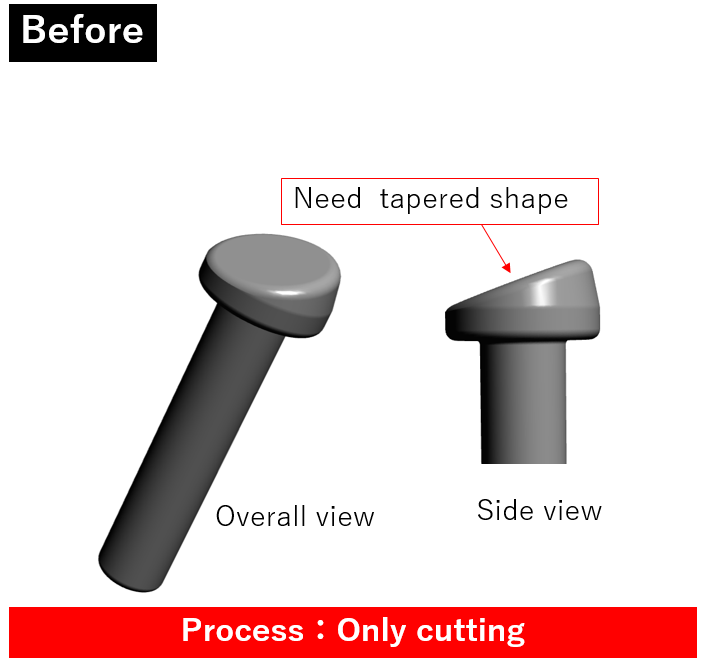

Until now, the customer had been processing products by cutting. Because the shape of the product was complex and the material was stainless steel, it was determined that other methods would be difficult, and the product was machined by cutting.

However, as mentioned at the beginning of this article, the customer wanted to reduce costs, and asked us if we could forge the product.

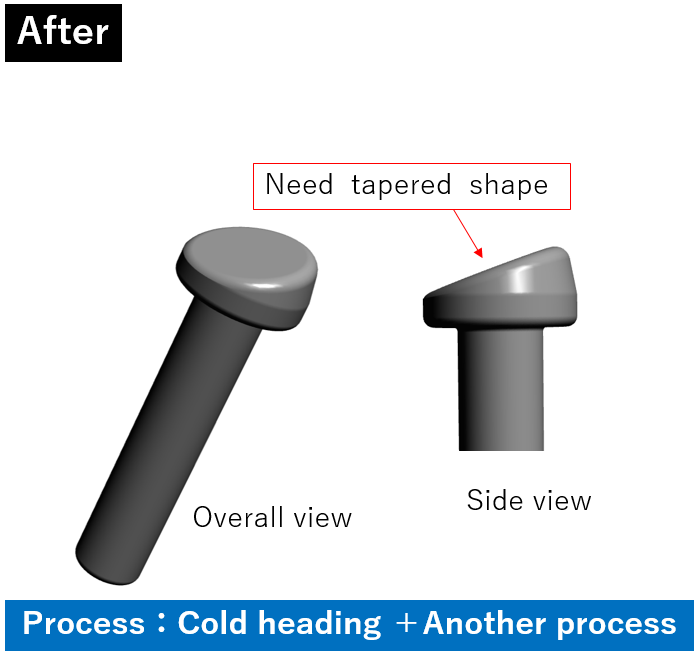

Therefore, we proposed a forging + secondary cutting process.

This product is characterized by its special head shape and stainless steel material.

Therefore, it was difficult for other companies to forge it, but we proposed forging + secondary machining and succeeded in forming it.

As a result, a cost reduction of about 30% was achieved, and the product has been successfully transferred to mass production.

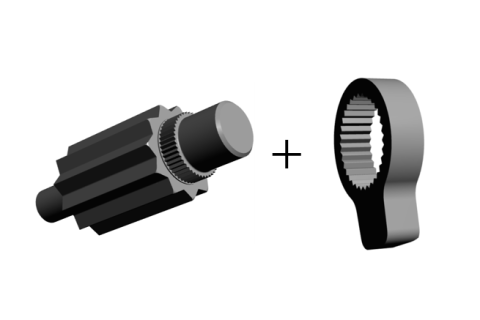

This is a consultation from a client regarding the conversion of a pin construction method. This is a proposal for a VA case in which only the manufacturing method was changed without changing the drawings, which is our specialty.

If you have any problems regarding the conversion of production method, please contact our Cold Forging/VA/VE Center.

We can solve your problems with our cold forging die design and development capabilities, and with over 100 pieces of manufacturing equipment, including a 9-stage parts former.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.