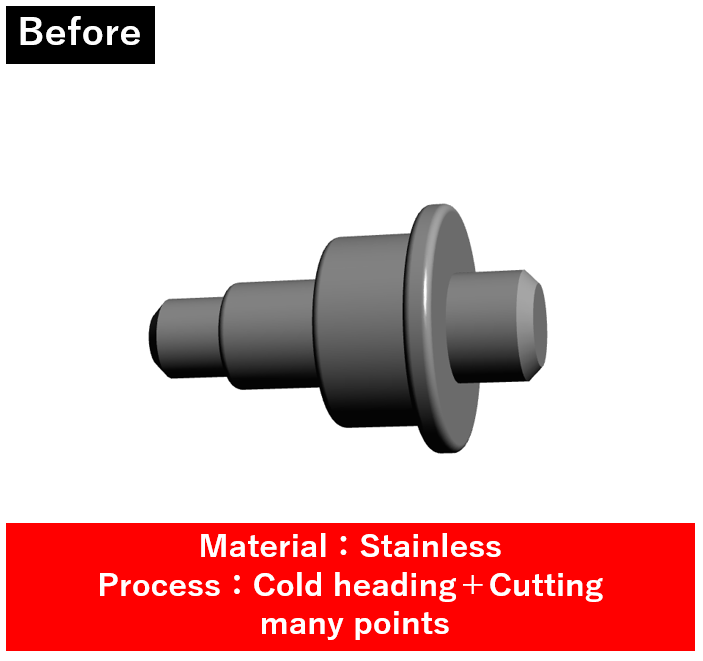

This is an example of a change of construction method and material for a shaft used at a door lock.

SUS304 was selected as the material for this product because corrosion resistance was required.

Due to the characteristics of the stainless steel material, the machining rate of this product was limited, and additional cutting work was required at several locations.

As a result, secondary machining was required, resulting in a high-cost product. (Conventional method is cold forging + secondary cutting)

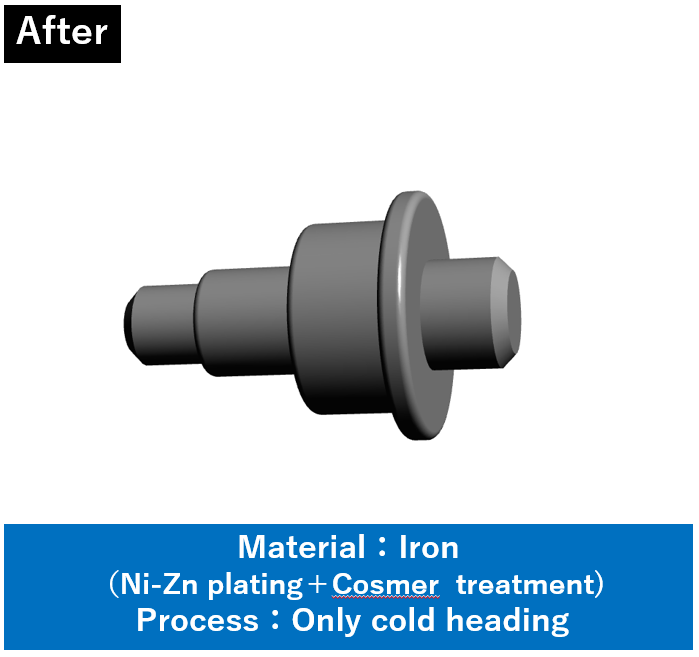

We proposed VA/VE so that the product could be formed only by cold forging.

When we confirmed the intended use of the product, we found that corrosion resistance was required and hardness was not important.

Therefore, we considered the possibility of using iron as the material and adding corrosion resistance by surface treatment in consideration of formability.

For the surface treatment, we selected "nickel-zinc alloy plating + cosmer treatment," which has excellent corrosion resistance.

When making a proposal, we present the customer with corrosion resistance test data from the surface treatment manufacturer. Furthermore, the corrosion resistance has been tested by salt spray test, and the white rust and red rust generation time is more than 2,000 hours, which shows outstanding corrosion resistance performance.

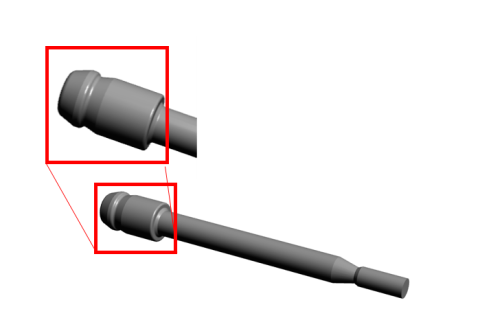

A customer consulted us regarding a change of shaft construction method and material.

This is a VA case study in which only the manufacturing method was changed while the drawings remained the same, which is our specialty.

If you have any questions or concerns regarding conversion of production method or change of material, please contact us at Cold Forging/VA/VE Center.

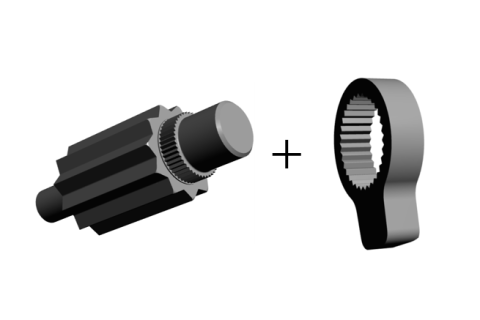

We can solve your problems with our cold forging die design and development capabilities, and with over 100 pieces of manufacturing equipment, including a 9-stage parts former.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.