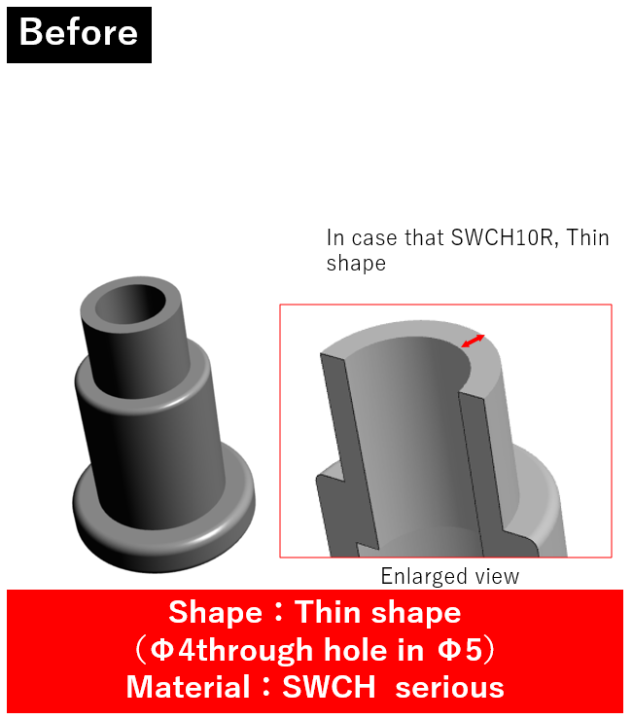

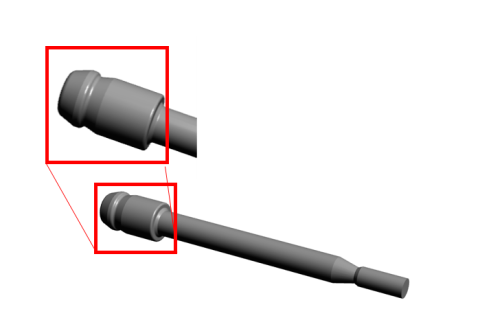

This is a case in which changing the shape and material of the collar became an issue.

The customer was asked to consult with us about a problem they were facing: they wanted to reduce the weight (SWCH10R).

The background of wanting to reduce weight was to change from steel to aluminum in order to improve fuel efficiency.

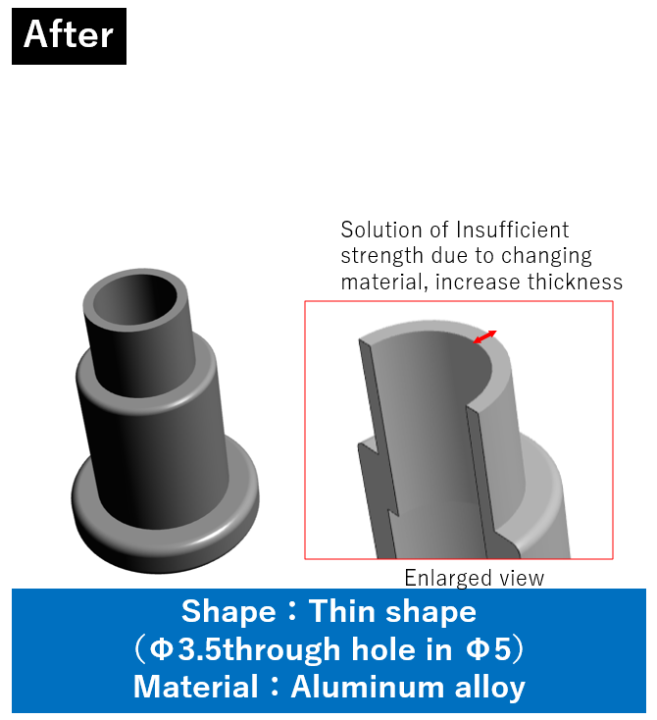

In response to a specific problem, we proposed to make a thinner hole and increase the thickness of the single wall, because the part made of A6061 heat-treated aluminum alloy was not strong enough. The proposal was to change the Φ4 through hole in the Φ5 section to a Φ3.5 through hole in the Φ5 section.

As a result, we were able to meet the customer's request, and the customer was satisfied with our proposal.

A customer consults with us regarding the conversion of color shape and material. This is a proposal for a VA case study in which we changed the shape and material, which is one of our specialties.

If you have any problems regarding shape and material, please contact our Cold Forging and VA/VE Center.

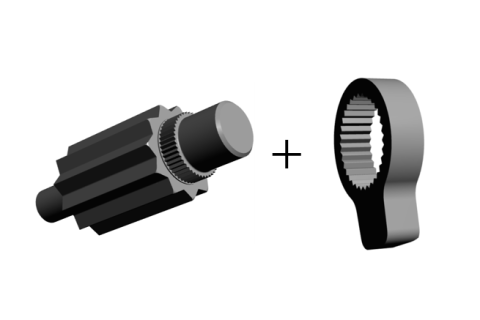

We can solve your problems with our cold forging die design and development capabilities and over 100 pieces of manufacturing equipment, including a 9-stage parts former.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.