This is a case in which the issue was to change the gear manufacturing method and integrate the parts.

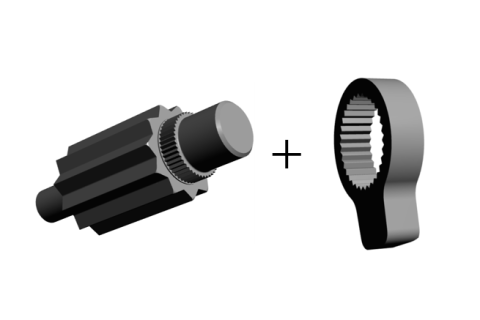

At the development stage, a two-part assembly of a shaft and gear (sintered product) was considered, but we were consulted to see if there was a way to further reduce costs.

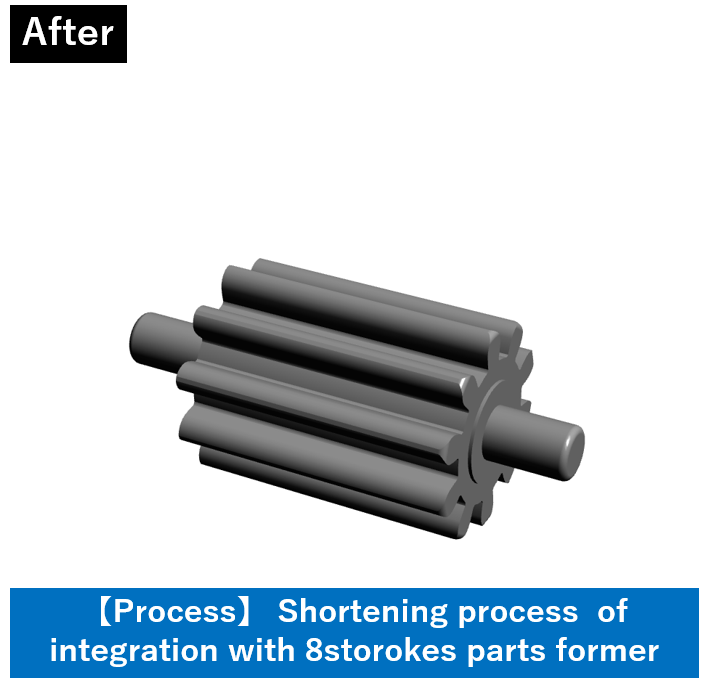

To address specific issues, we have achieved a reduction in the press-in process and cost by integrating molding with an 8-stage parts former.

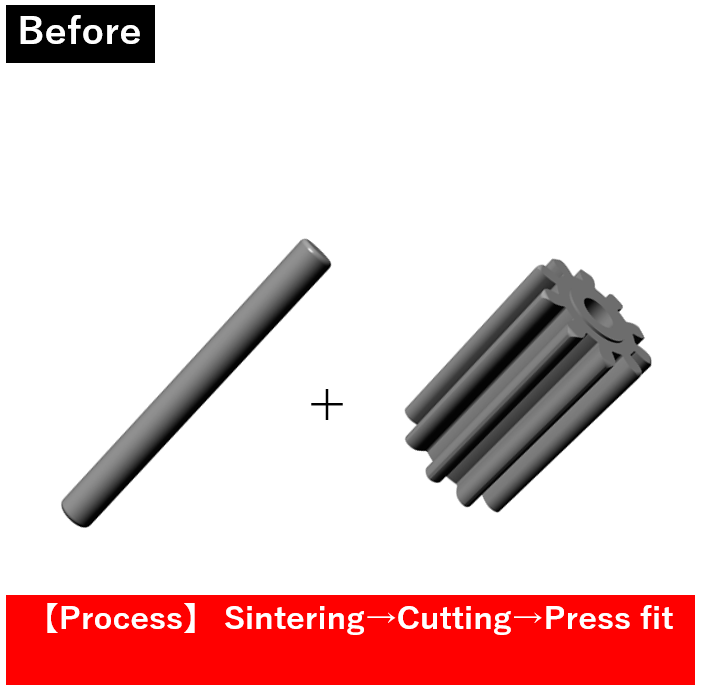

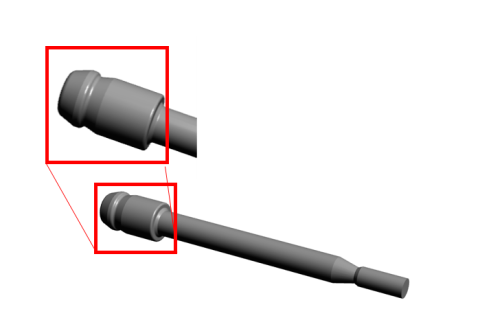

The product originally consisted of two parts. The gear was formed by a powder press, and the pin made of SUS was finished by cutting with an automatic machine, and then the pin was inserted and assembled to the gear using a press-fit machine.

The key point of our proposal this time was to reduce the number of processes.

As a result, the three processes (sintering, cutting, and assembly (press fitting)) were reduced to one process, resulting in the following three merits.

(1) Cost reduction by reducing man-hours

(2) Increased strength through integration

(3) Increased hardness due to cold forge hardening of the gear section

Although the final product was not mass-produced, the customer appreciated the high quality of the technology.

A client consulted us regarding a change in gear construction method. This is a proposal for a VE case involving drawing changes, which is one of our specialties.

If you have any problems regarding the conversion of production methods, please contact our Cold Forging/VA/VE Center.

We can solve your problems with our cold forging die design and development capabilities, and our over 100 manufacturing machines, including 9-stage and 8-stage parts formers.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.