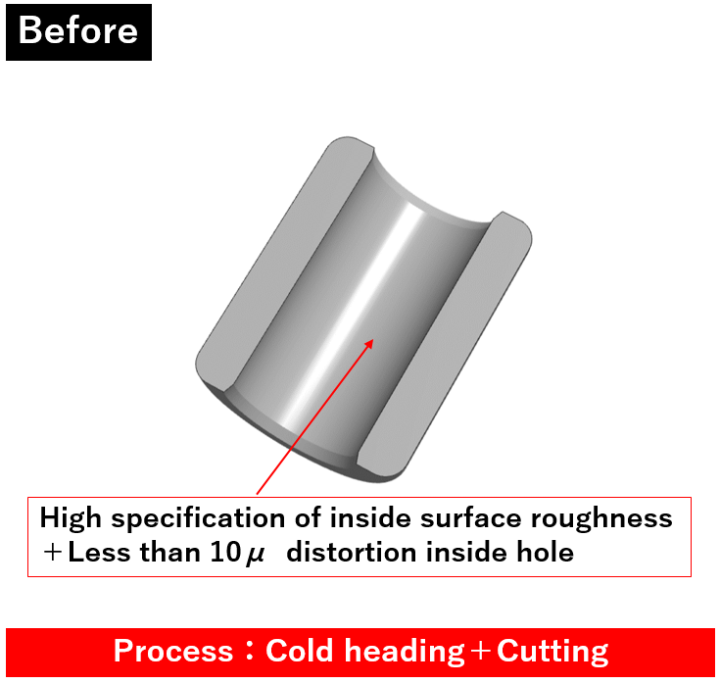

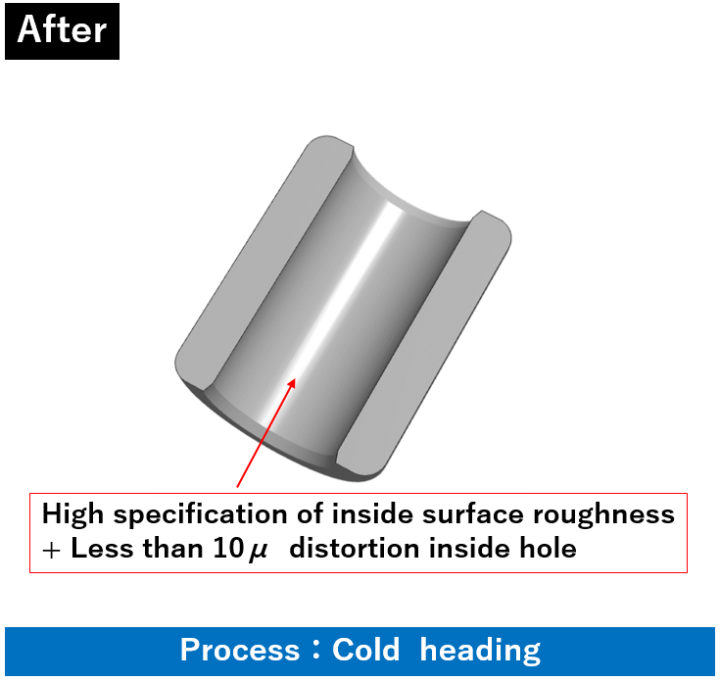

This is an example of a case in which the challenge was to change the color production method.

The customer's problem was that the inside diameter surface roughness was so severe that additional cutting labor was required, and the customer asked us if we could clean up the cutting surface of the inside diameter. According to the drawing instructions, the swell of the bore was requested to be less than 10μm.

In response to a specific problem, we proposed a one-shot forging process.

The key point of the proposal was to add a process to clean the surface by forging after removing the hole.

We submitted the proposal for a forging finish without cutting and an inside diameter roughness finish.

As a result, the surface roughness was cleared, costs were reduced, and production speed was improved.

We were able to satisfy the customer by reducing the swell of the inside diameter to less than 10μm, which is difficult for other companies to do.

This is a consultation from a client regarding a color construction method conversion.

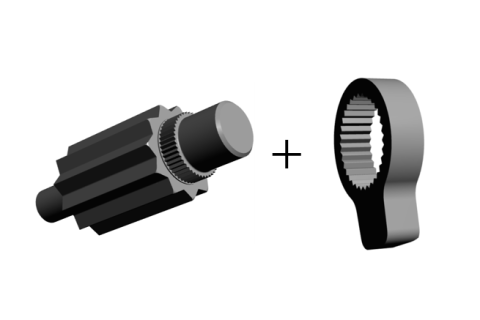

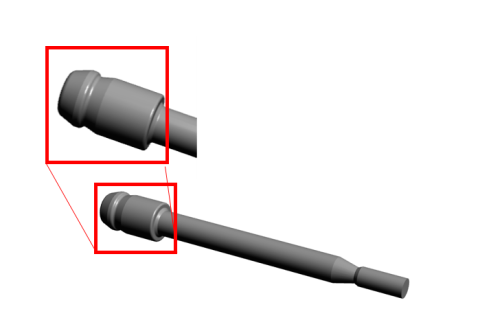

This is a proposal for a VA case in which only the manufacturing method was changed without changing the drawings, which is our specialty.

If you have any problems regarding the conversion of production method, please contact our Cold Forging/VA/VE Center.

We can solve your problems with our cold forging die design and development capabilities, and with over 100 pieces of manufacturing equipment, including a 9-stage parts former.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.