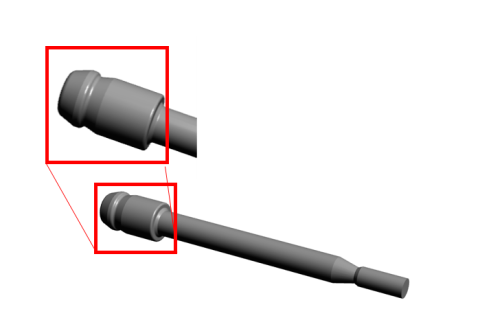

This is a case in which the integration of parts for nozzles used in injectors became an issue.

The current customer was troubled by the high unit price of the product.

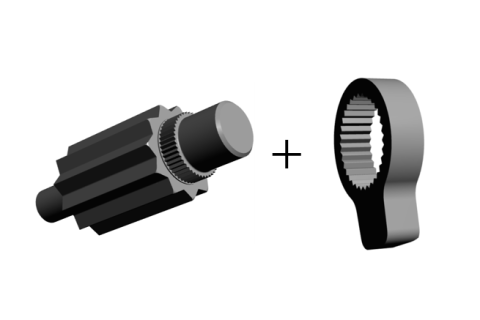

In response to a specific challenge, we proposed the integration of two parts.

The key point of our proposal was to reduce the number of processes.

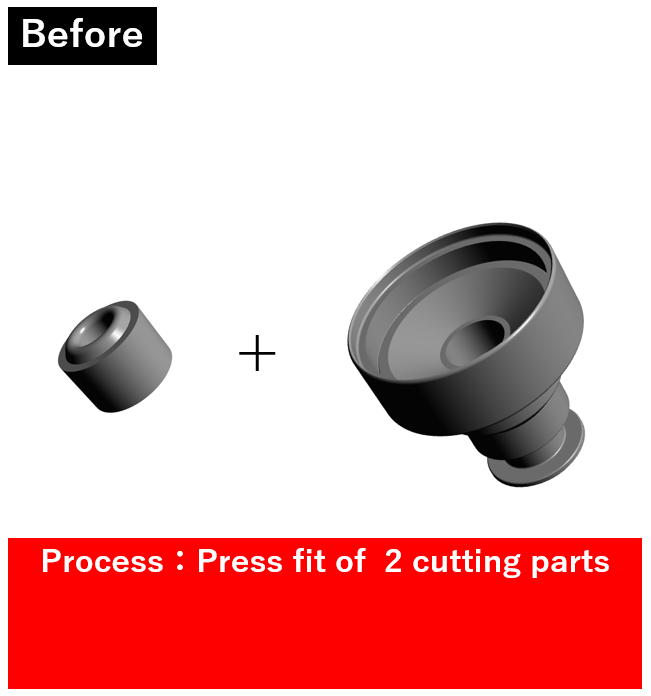

The conventional press-fit process was eliminated by integrating the two parts.

As a result, material and processing costs were reduced and production speed was improved by integrating the two parts, whereas in the past two types of all-cut parts were press-fitted together.

A customer consulted us regarding the integration of nozzle parts.

This is a VE case in which we made a drawing change, which is one of our specialties, and proposed replacement from cutting.

If you have any questions or concerns about the integration of parts, please contact our Cold Forging/VA/VE Center.

We can solve your problems with our cold forging die design and development capabilities and our over 100 manufacturing machines, including 9-stage parts formers.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.