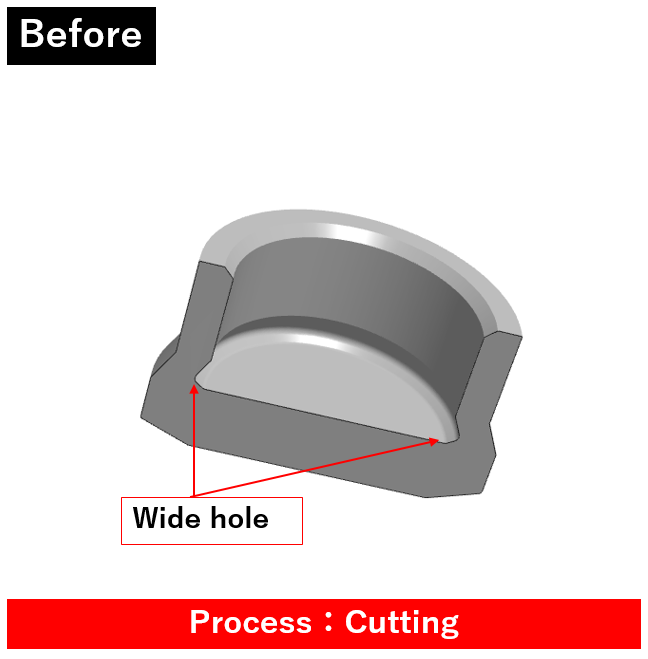

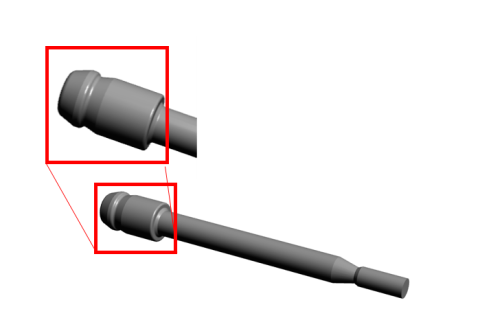

This is a case in which the challenge was to change the method of production of caps used in the prevention of spring dislodging.

The customer needed a bag hole to prevent the spring from falling out, but cutting would be too costly, so the customer wanted to reduce costs by using a different method.

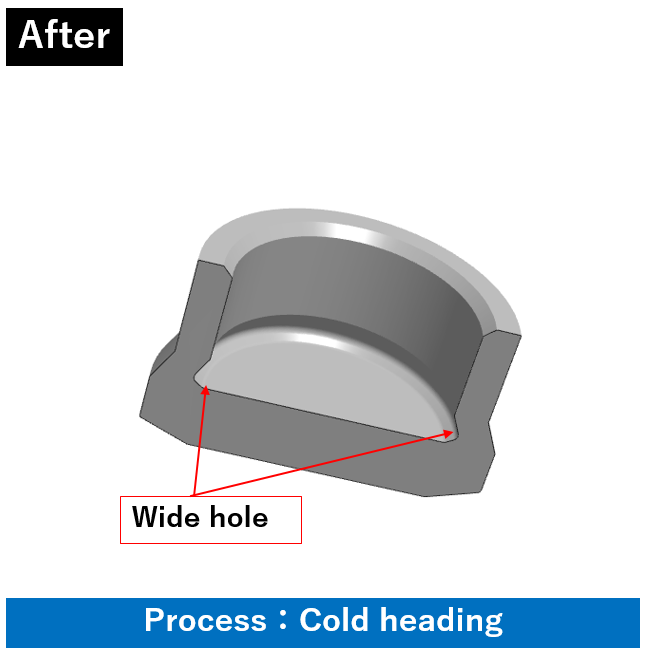

In response to a specific problem, we proposed a one-shot forging process.

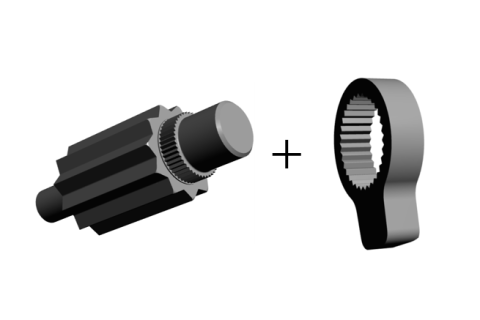

The key point of the proposal was that the inner diameter of the product and the outer diameter of the spring should match, so that the spring would be held in the bag hole and would not fall out.

As a result, we were able to reduce costs by changing from cutting to cold forging.

This is a consultation from a client regarding the conversion of a cap construction method. This is a proposal for a VA case in which only the manufacturing method was changed without changing the drawings, which is our specialty.

If you have any questions or concerns regarding the conversion of production method, please contact us at the Cold Forging/VA/VE Center.

We can solve your problems with our cold forging die design and development capabilities, and with over 100 pieces of manufacturing equipment, including a 9-stage parts former.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.