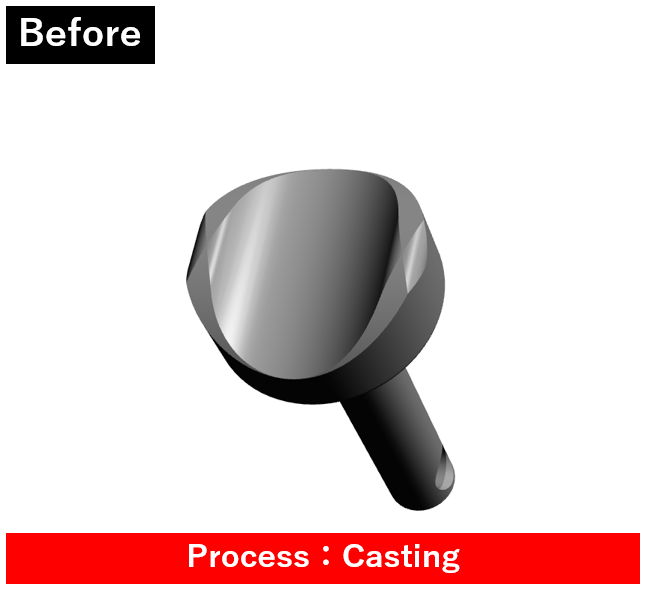

This is a case in which the challenge was to change the manufacturing method for buttons used in semiconductor manufacturing equipment.

The customer's current problem was that they were using the lost wax process, but "cast cavities" had formed and were breaking, and man-hours were wasted on inspecting the "cast cavities.

The customer was considering using a different method because of the high incidence of defects and the poor mold durability.

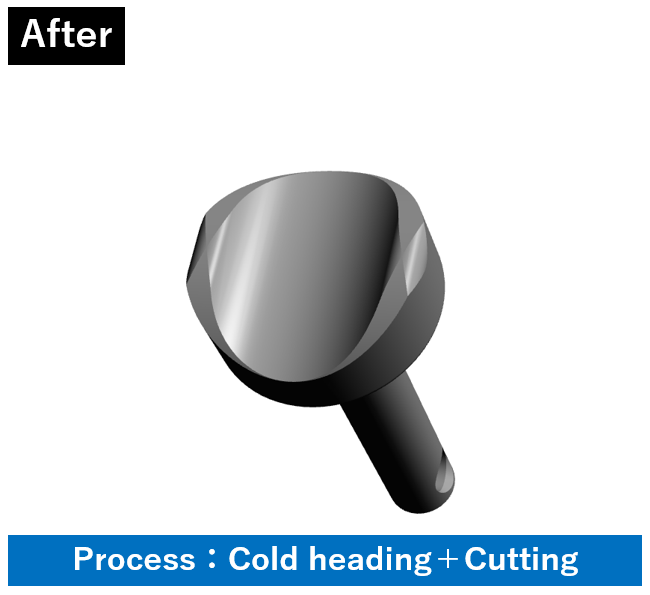

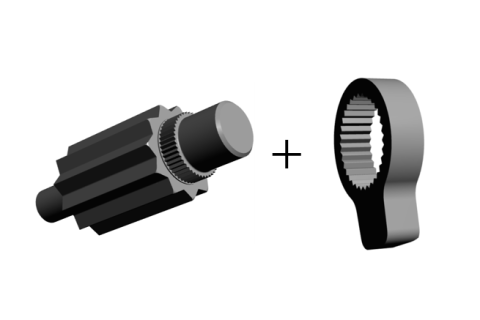

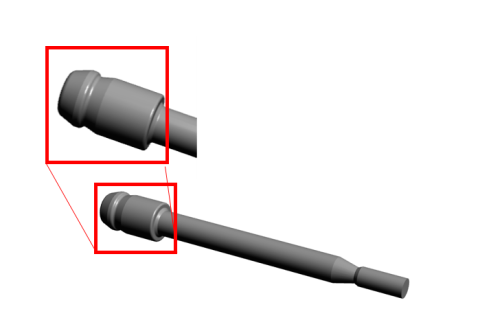

To meet the specific challenge, we proposed a cold forging + cutting solution.

The key point of our proposal was to manufacture the product by cold forging, making full use of our technical capabilities.

As a result, this product was rejected by other companies because it was very difficult to manufacture the head, but we were able to achieve the following three points compared to the conventional method, and the customer was satisfied.

(1) Cost reduction

(2) Conversion of production method + no inspection

(3) Zero number of NG due to "casting nests

A client consulted us regarding the conversion of a button construction method. This is a proposal for a VA case in which only the manufacturing method was changed without changing the drawings, which is our specialty.

If you have any problems regarding the conversion of production method, please contact our Cold Forging/VA/VE Center.

We can solve your problems with our cold forging die design and development capabilities, and with our more than 100 manufacturing facilities, including a 9-stage parts former.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.