This is an example of a gear manufacturing method conversion challenge. The current customer's concern is to ensure the required strength of the gears.

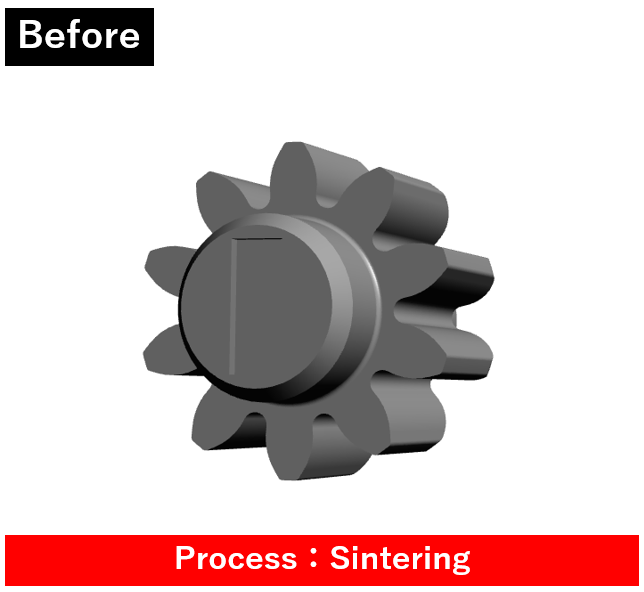

Initially, the customer was considering sintering production.

However, although it was possible to form complicated shapes, it was not possible to secure the required strength, so they consulted with us.

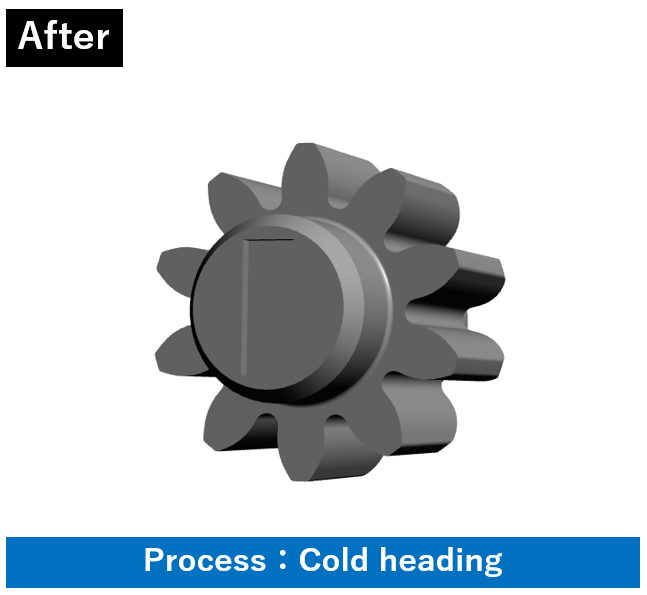

In response to a specific challenge, we proposed cold forging while ensuring gear accuracy.

The key point of our proposal was to ensure the necessary strength of the gears.

By implementing the above points, we were able to reduce costs and improve productivity.

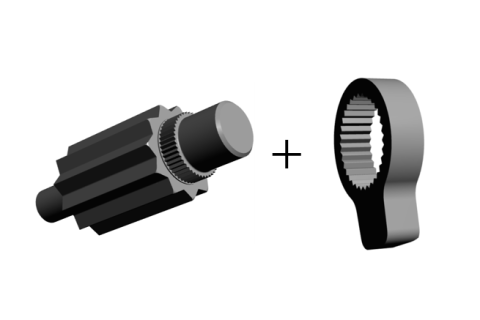

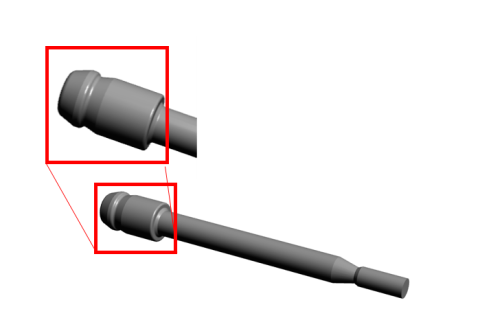

As a pioneer in metal processing, we have been able to meet our customers' needs with our cold forging technology, even for products with complex and difficult shapes.

We have more than 130 VA/VE proposals per year. Please contact us for more information.

This is a consultation from a customer regarding the conversion of a gear manufacturing method. This is a proposal for a VA case in which only the production method was changed without changing the drawings, which is our specialty, and which could be formed by cold forging.

If you have any problems regarding the conversion of production methods, please contact our Cold Forging/VA/VE Center.

We can solve your problems with our cold forging die design and development capabilities, and with over 100 pieces of manufacturing equipment, including a 9-stage parts former.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.