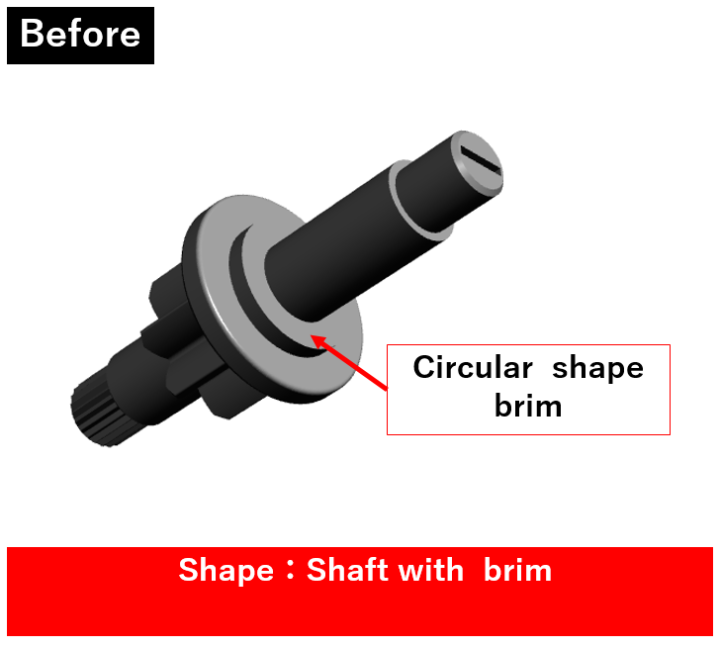

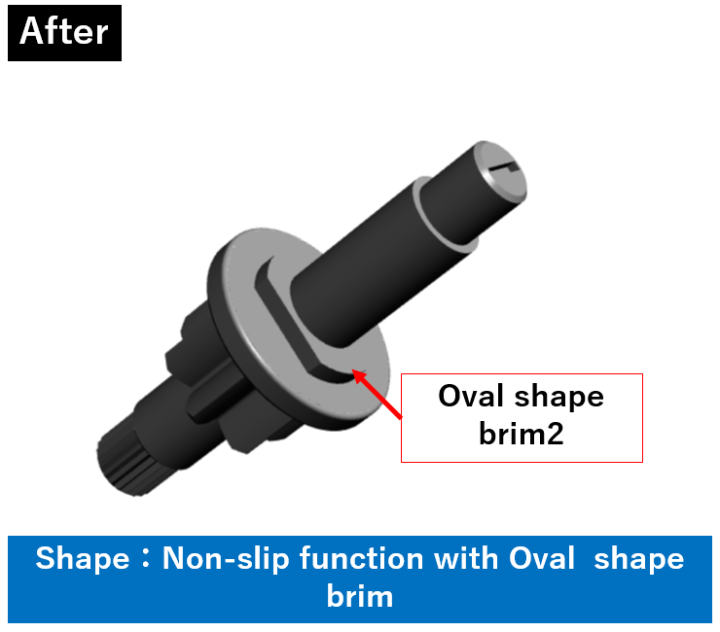

This is an example of a proposal to change the shape of a gear shaft while maintaining its function.

The current customer's problem is that a non-turn function, which was not originally envisioned, is now required.

The customer consulted us because they needed to consider a shape that would satisfy the function while maintaining the cost.

In response to a specific challenge, we proposed a small-format shape that minimizes load during molding so as not to increase costs.

The key to cost reduction was to change to a small oval shape to prevent turning.

As a result, we were able to start up the product in three months and develop a product that fulfilled the functionality, despite the short time required for start-up.

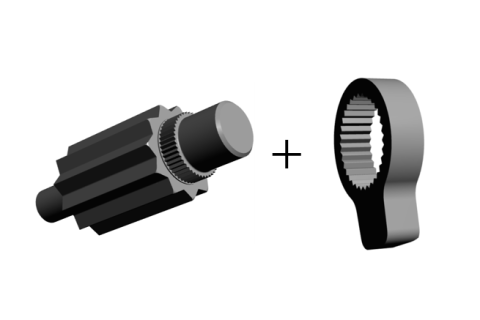

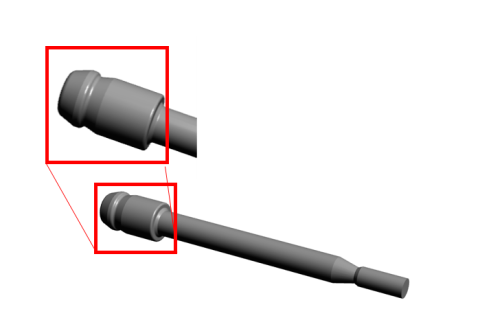

A customer is consulting with us regarding a change in the shape of a gear shaft. It is possible to change the gear shaft to a small size by cold forging.

Please contact our Cold Forging/VA/VE Center if you have any questions or concerns about shape modification.

We can solve your problems with our cold forging die design and development capabilities and over 100 pieces of manufacturing equipment, including a 9-stage parts former.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.