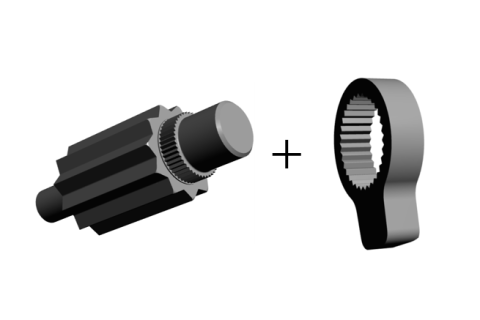

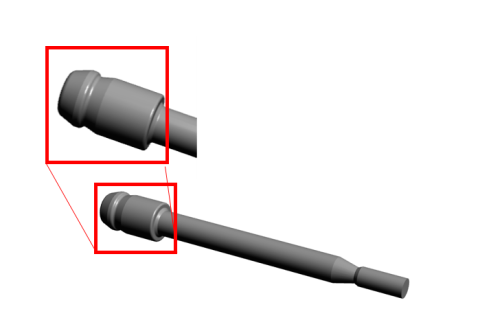

This is an example of an involute shaft that presented a challenge to change the shape of the shaft.

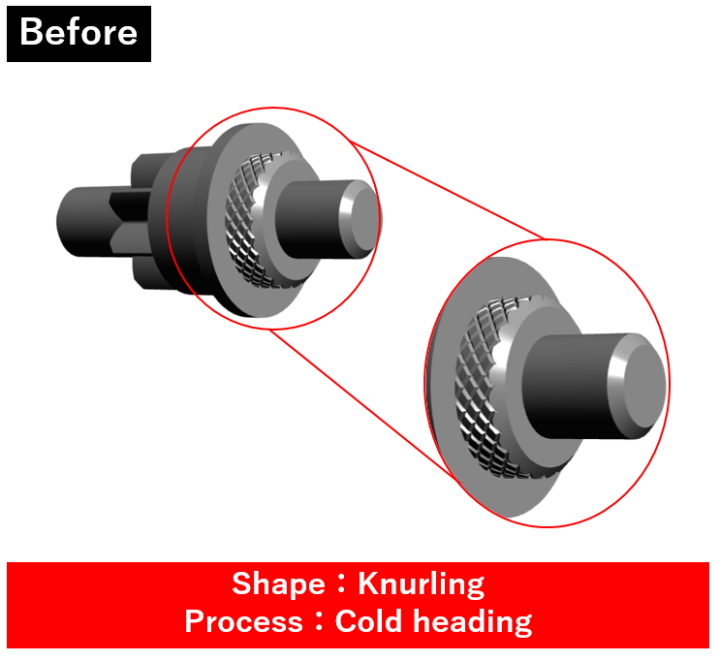

The customer's current problem was that the resin detouring shape (knurling) initially considered in the design had limited strength, and the customer was concerned about the shape to secure the required torque.

Knurling only increased the pitch but limited the torque.

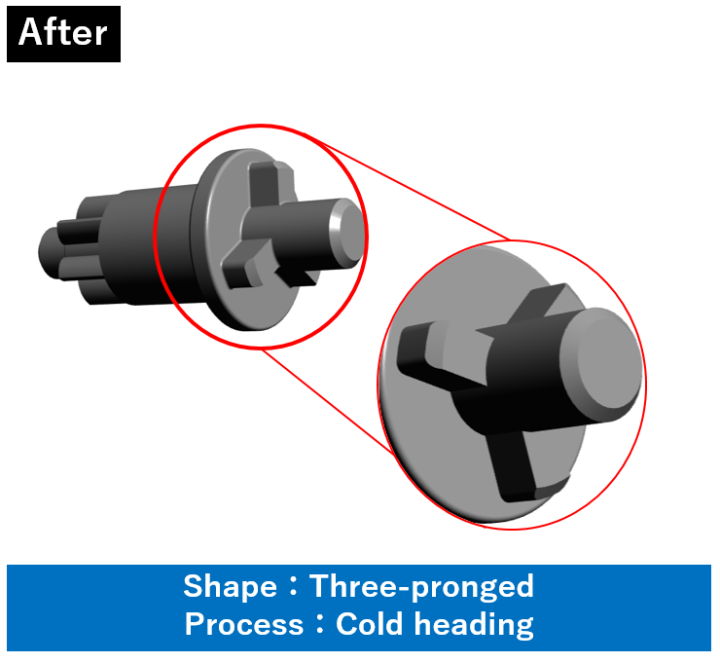

Therefore, we proposed a trilateral shape that is even stronger than ours and can be formed by cold forging.

As a result, we were able to reduce knurling man-hours, product cost, and part mass while meeting the required strength.

The change in shape also enabled a 30% reduction in cost compared to the current design. As a side effect, the product was also easier to assemble on the line, and the customer was satisfied with the result.

A customer consulted us regarding cost reduction of involute shafts.

This is a proposal for a VE case in which we propose a replacement from cutting by changing the drawings, which is our specialty.

If you have any questions or concerns about cold forging, please contact our Cold Forging/VA/VE Center.

We can solve your problems with our cold forging die design and development capabilities and over 100 pieces of manufacturing equipment, including 9-stage parts formers.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.