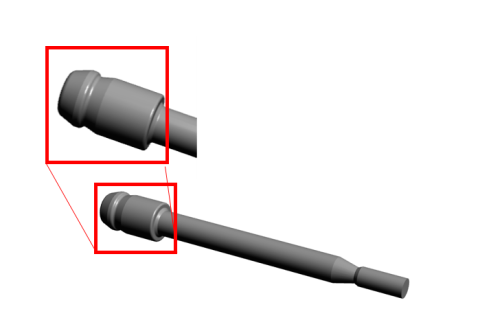

This is an example of a shaft shape change that became an issue.

The company was asked to make a cost reduction for the next generation of motor shafts, as product competitiveness to win global competition was urgently needed and cost reduction was essential.

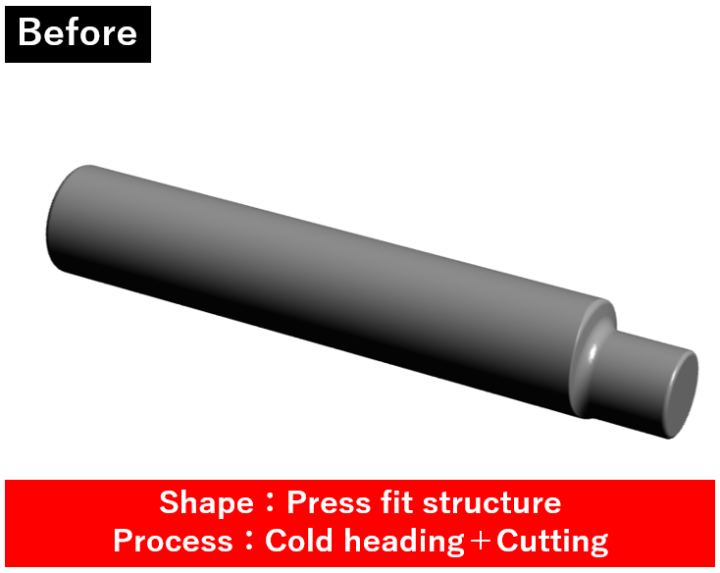

In the conventional method, the press-fit point was done by cutting.

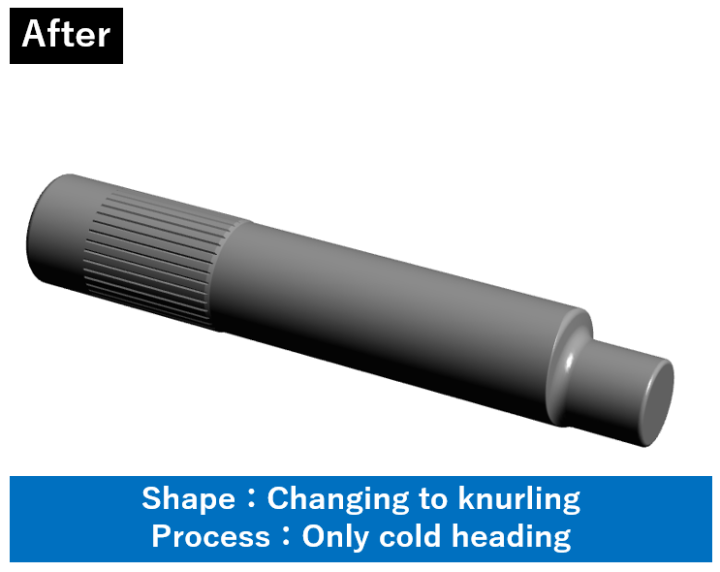

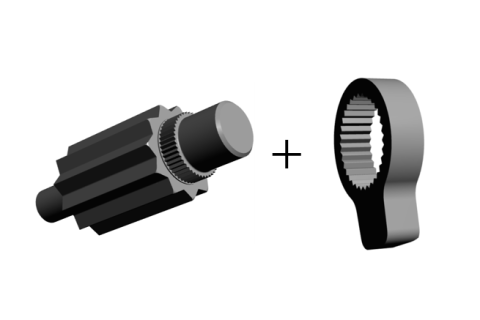

In response to this specific issue, we proposed that the shaft could be knurled to have the same functionality while reducing man-hours and improving productivity.

As a result, we were able to reduce man-hours and improve productivity while maintaining accuracy and functionality. As a result, we were able to reduce the cost by 40%, mass by 10%, and man-hours by 20% compared to the current cost by changing the shape.

The reduced cost of the product will give it a competitive advantage in the next generation of motor shafts.

A customer consulted us regarding cost reduction of shafts. We propose a VE case study by changing the drawings, which is our specialty, and replacing the cutting process.

If you have any questions or concerns about cold forging, please contact our Cold Forging/VA/VE Center.

We can solve your problems with our cold forging die design and development capabilities and over 100 pieces of manufacturing equipment, including a 9-stage parts former.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.