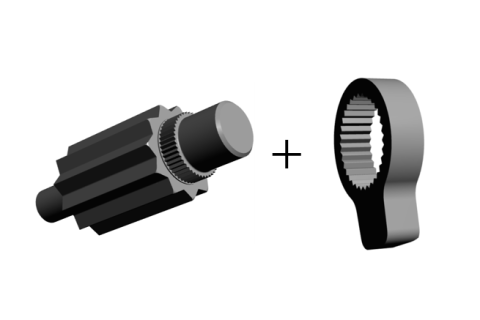

This is a case in which the challenge was to reduce the cost of components used in an auto tensioner that maintains a constant tension on the belt and automatically controls the tension.

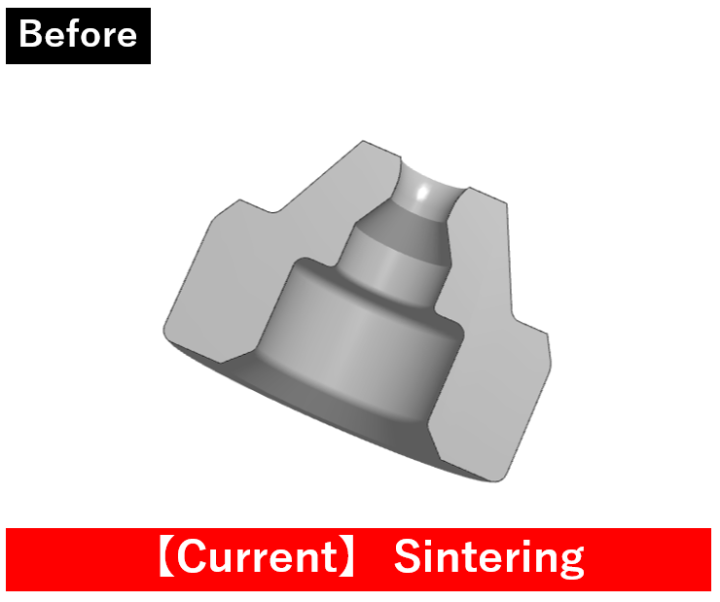

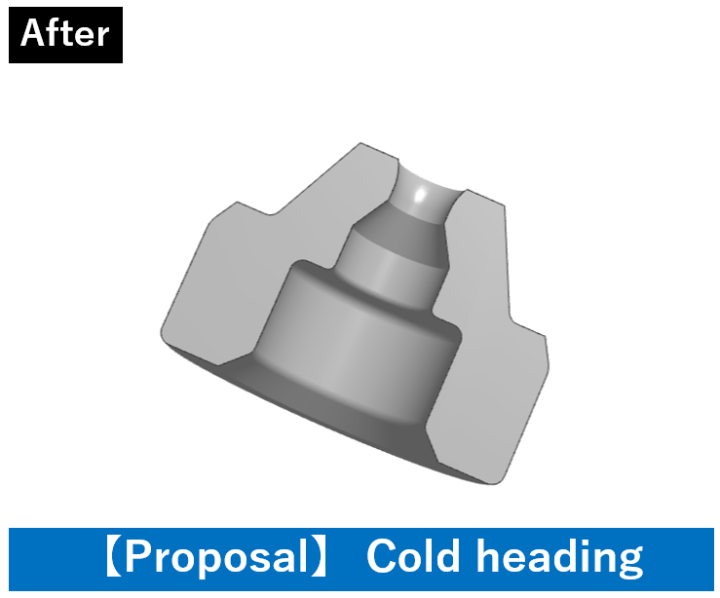

The customer's concern was that the cost reduction of tensioners for the automotive industry had become a necessity due to the catch-up by the customer's competitors. Currently, the customer is forming the parts by sintering, but the same process has limitations on cost reduction, so the customer requested us to consider forging the parts.

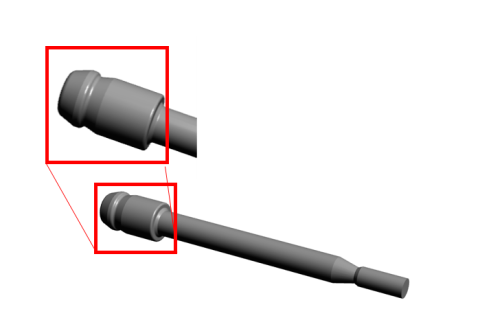

We proposed a shape that could be cold forged so as not to compromise the consistency and functionality of the mating part.

The key to cost reduction was to forge parts that had been made using a different process. There are two reasons why our company was chosen.

1. cold forging

Because of our high production technology, we can improve the accuracy and strength of products that are difficult to forge with other companies.

2. Full lineup of production facilities

We have a large number of stages, including a 9-stage parts former, which enables cost reduction and mass production.

In the process of proposing cold forgeable shapes, the strength of the sealing surface has been improved, which also improves durability and airtightness. In terms of cost, which was one of the initial issues, we succeeded in reducing the cost compared to the conventional product, and mass production through forging also contributed to speeding up the supply.

A customer consulted us regarding cost reduction of parts used in auto tensioners.

Utilizing our strength in die development, we succeeded in cold forging a product with a shape that was considered difficult by other companies.

As in this case, we can not only solve cost issues, but also offer proposals to improve the functionality of the parts. If you have any problems related to cost reduction for products manufactured by other methods, please contact our Cold Forging/VA/VE Center.

We can solve your problems with our cold forging die design and development capabilities and over 100 pieces of manufacturing equipment, including a 9-stage parts former.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.