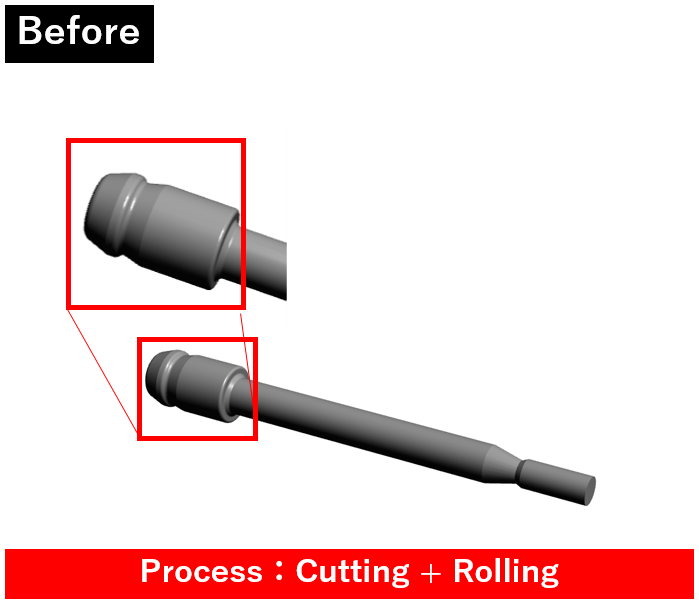

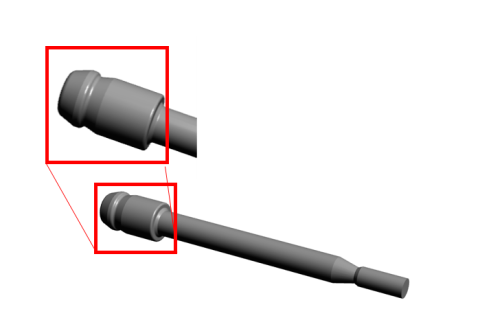

This is an example of an issue regarding the shaft production method. The shaft had been manufactured by all-cutting + rolling, but because of the need to increase production from the previous lot, the customer wanted to lower the manufacturing cost per unit, and asked us to help.

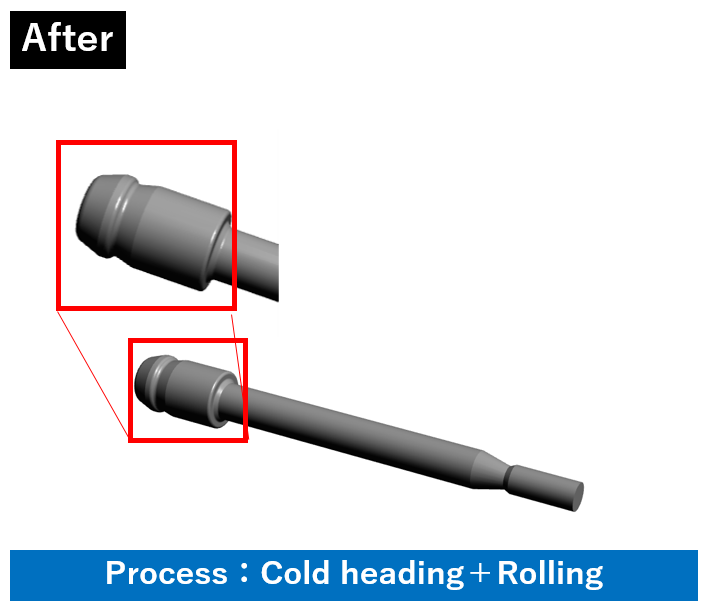

Therefore, we proposed to change the method of production by utilizing cold forging (all cutting + rolling → cold forging + rolling).

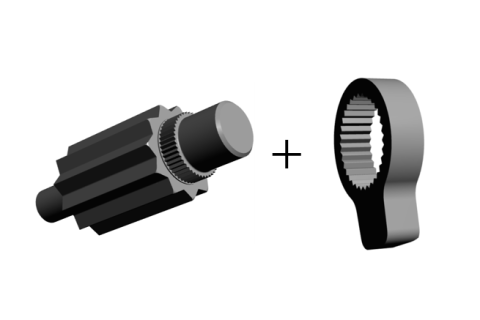

The grooves are processed by rolling, and all the external forming is done by forging. Since this is a multi-stage shaft, forging requires a multi-stage parts former and the ability to design and manufacture dies.

As a result of this proposal, we were able to reduce costs by approximately 20% and improve production capacity.

This is a case of consultation regarding revision of production method and cost reduction for mass production of shafts.

The cost reduction was successfully achieved by cold forging and rolling instead of cutting and rolling.

If you are considering cost reduction by changing production methods, please contact the Cold Forging/VA/VE Center.

We can solve your problems with our cold forging die design and development capabilities and over 100 pieces of manufacturing equipment, including a 9-stage parts former.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.