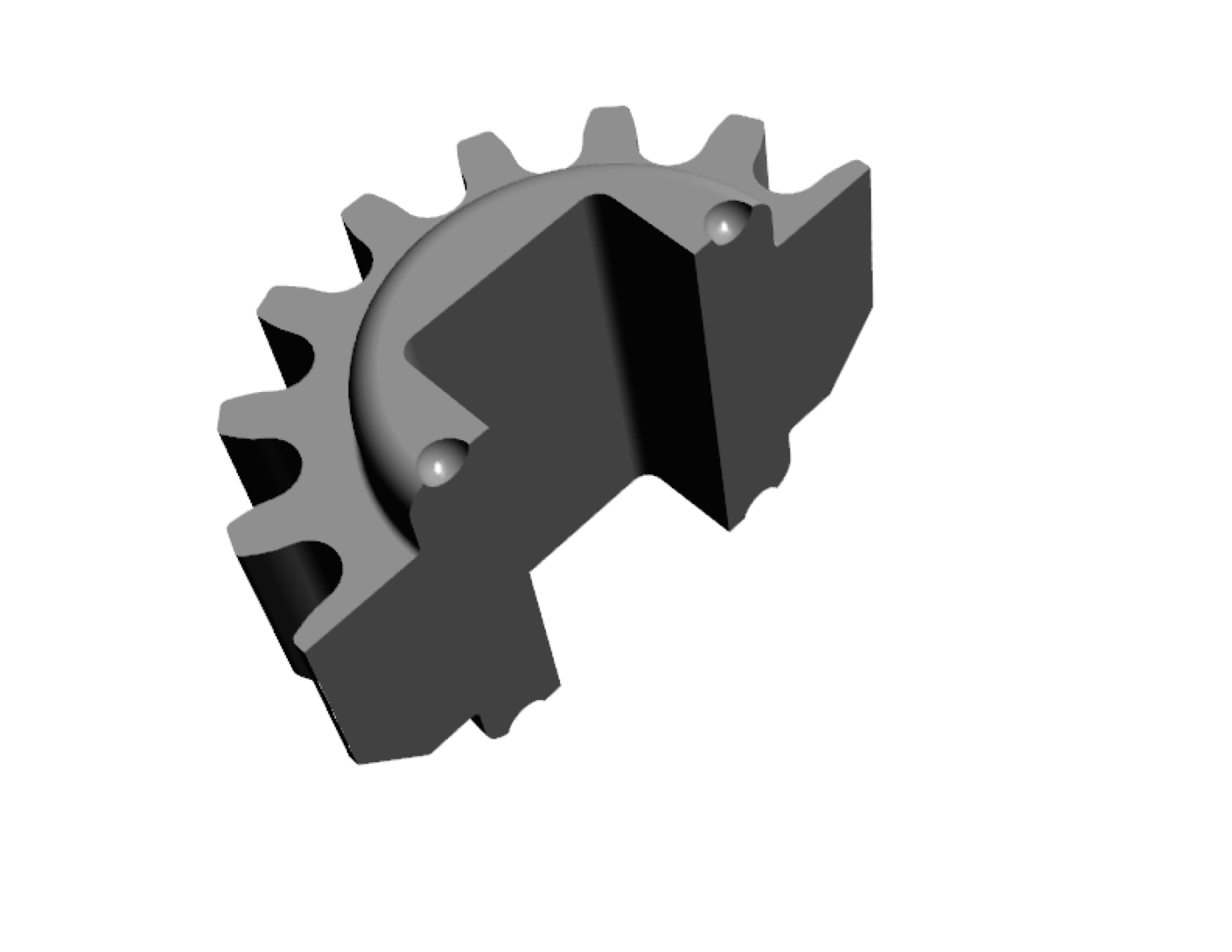

This example is an automobile seat component. It is characterized by the fact that the outer diameter is a gear and the inner diameter is a square hole.

The part had been designed using sintering, but the customer was considering a review of the manufacturing method with cost reduction and increased strength in mind.

Therefore, we proposed the use of forging.

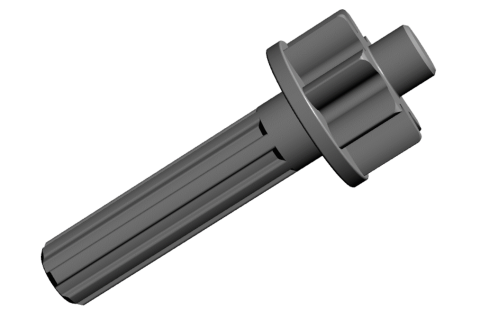

The bottleneck in the forging process was the square hole in the center. Compared to a round hole, drilling a square hole in the bore while maintaining the gear shape on the outside is much more difficult. We were able to overcome this difficulty by utilizing our die development capabilities and multi-stage parts former.

We had planned to use high-carbon steel and tempering as the material, but we proposed replacing it with low-carbon steel and carburizing heat treatment in consideration of the number of die lives and mass productivity.

We also took heading hardening into consideration when selecting the material, and the customer was satisfied with both the strength and quality of the product, which led to its adoption.

Arai Parts Co., Ltd. which operates the "Cold Forging/VA/VE Center" has abundant experience in manufacturing complex shaped parts with a square bore and gear-shaped outer diameter. Please contact us if you are having trouble with gear mass production.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.