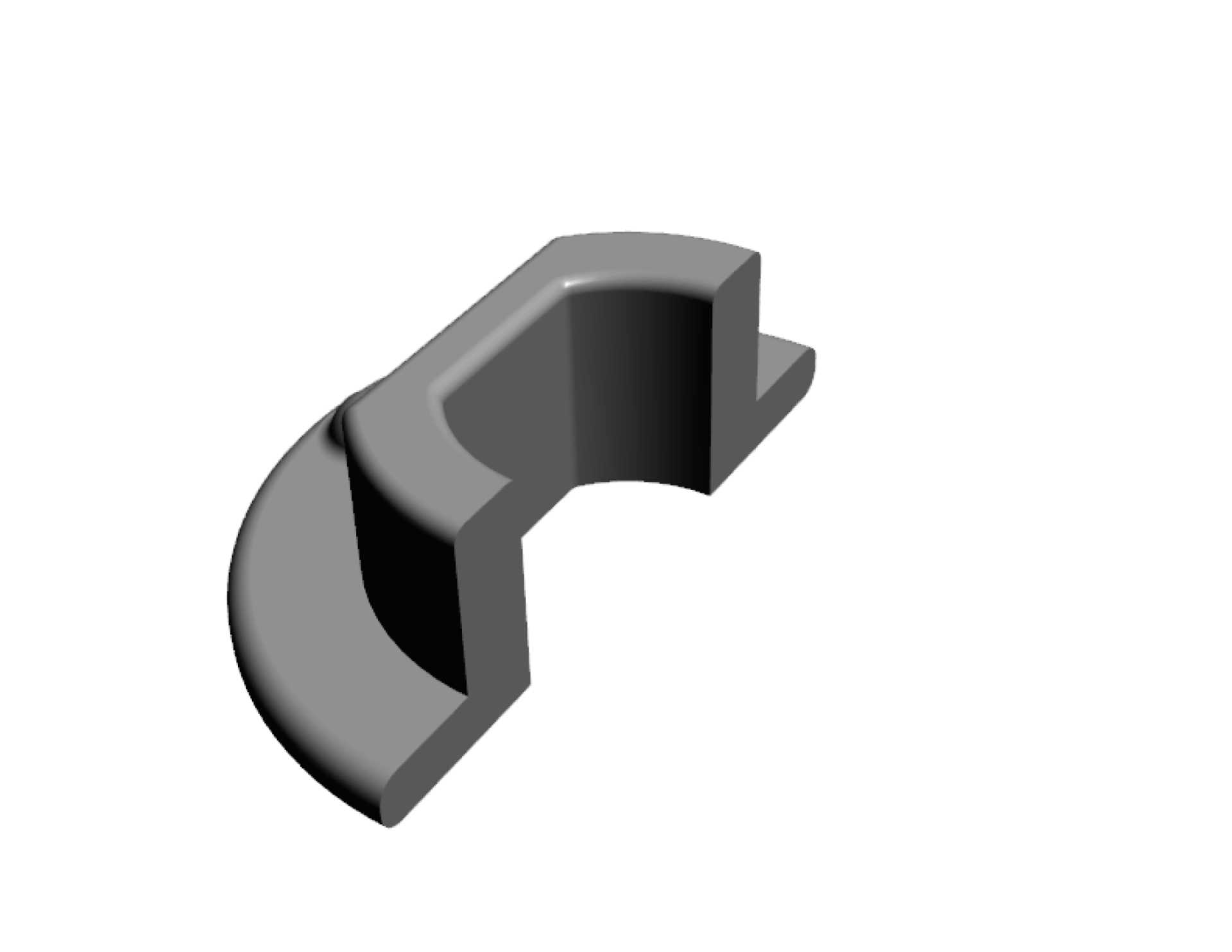

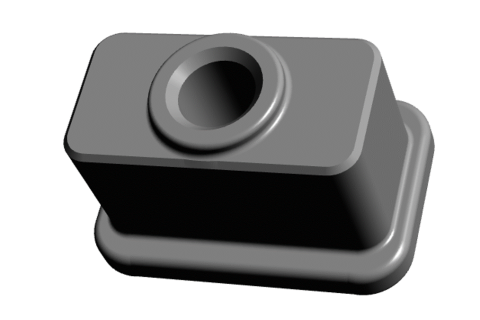

This example is an automobile seat component. The function of the product requires the bushing to be welded to the mating part, and the projection (protrusion) for welding was formed by forging.

The inner diameter of the bushing has a small-sized hole as a shape feature. It is more difficult to forge a small-sized hole than a round hole, and it is difficult for cold forging with a small number of steps, such as 2D3B headers.

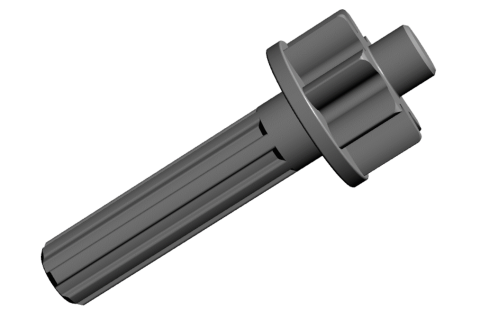

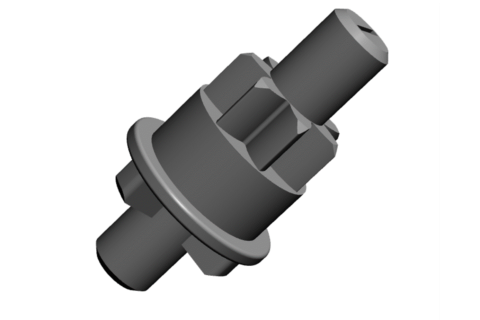

In this case, we made full use of a multi-stage parts former to form the projection (projection part) and the koban hole using only the former, achieving a significant cost reduction.

Arai Parts co., ltd., which operates the "Cold Forging/VA/VE Center," is also capable of forging all bushings with irregularly shaped holes and projections, as in this product. If you are considering cost reduction by cutting, please contact us.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.