This case is a product that is a part of a power backdoor, which was conventionally made by forming two parts by heading and assembling them.

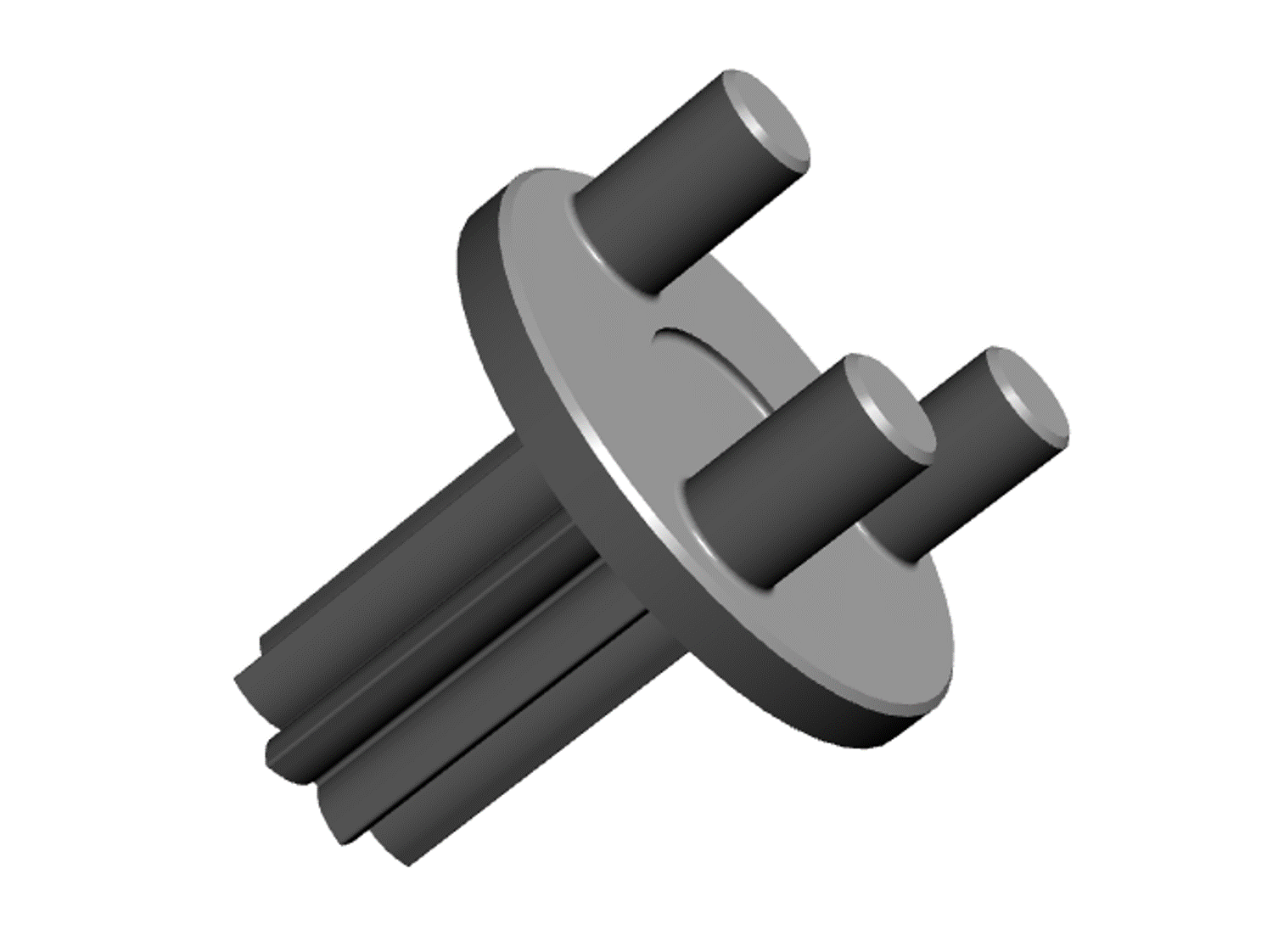

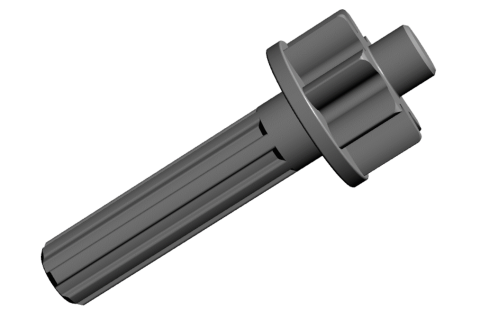

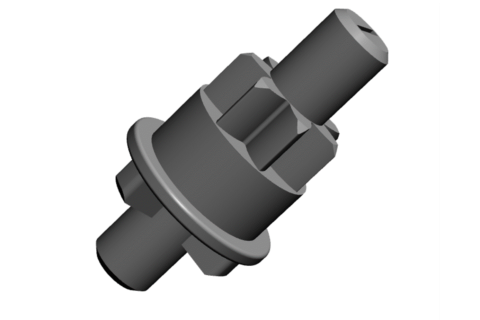

As you can see in the photo, the product used to consist of two parts because of the extremely difficult shape of the power gear and three legs.

We proposed a shape that would allow integration in accordance with the customer's requirements. Specifically, three legs were formed by forging and their lengths were aligned by cutting.

This change in production method has resulted in a cost reduction compared to a two-part configuration.

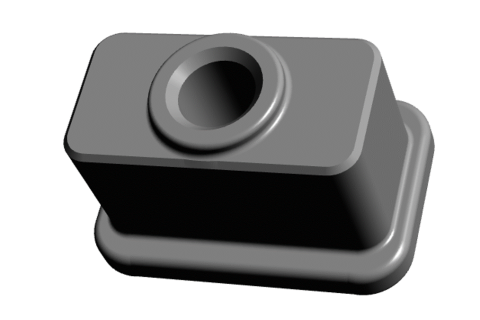

Arai Parts Co., Ltd. operates the "Cold Forging/VA/VE Center," and has many examples of converting the conventional two-part product into a single unit, which not only reduces costs but also improves strength.

If you are considering QCD kaizen through integration of products, please contact us.

Cold Forging/VA/VE CenterTo contact the Cold Forging/VA/VE Center,

Please contact us by Tel or by filling out the inquiry form.

If yo uare in a hurry, please give us a call.